Sheet-Fed UV/WB Coating System | High-Gloss & Matte Finishing for Digital & Offset Prints

Modular Design: Feeder + Coater + Dryer + Stacker for flexible configuration.

Wide Material Compatibility: 100–500gsm sheets, digital prints, packaging boards, photo media.

Superior Adhesion Technology: Optional primer unit for difficult surfaces (toner, Indigo, inkjet).

Multiple Finishing Effects: Gloss, matte, soft-touch, anti-scratch, and water-based coatings.

High-Speed Production: Up to 25 m/min with stable feeding and stacking.

Future-Proof System: Compatible with IR, UV, LED-UV, extended dryer zones, and corona units.

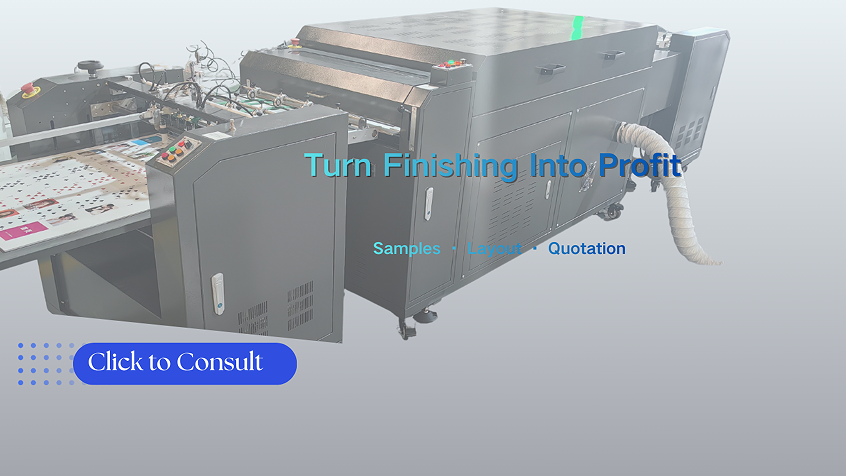

Sheet-Fed UV / Water-Based Coater – Compact Print Finishing Line

— Professional Offline Coater for Digital Printing, Packaging & Photo Finishing

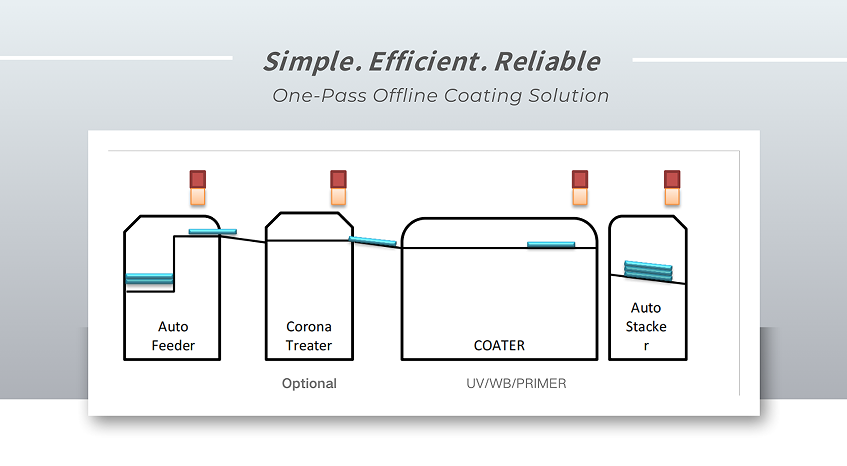

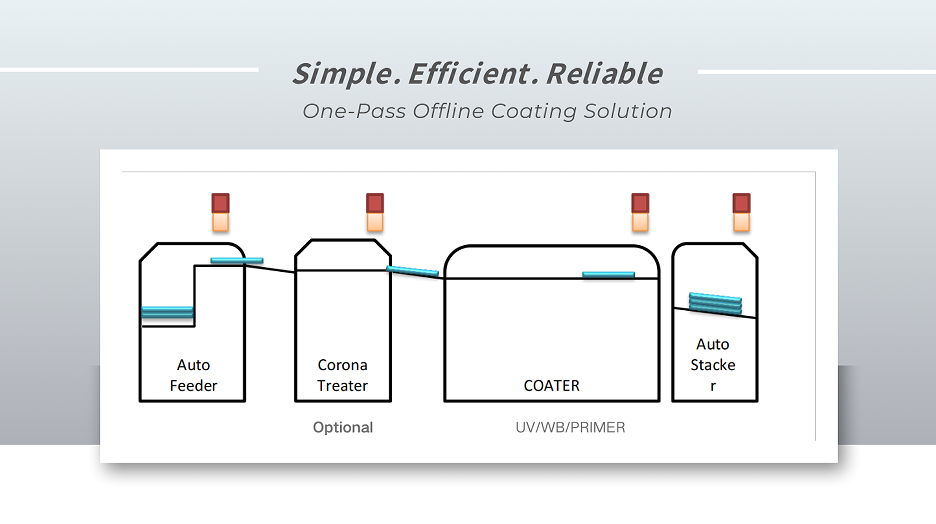

Overview — A Versatile One-Pass Coating Solution for Everyday Production

The Double100 Sheet-Fed UV / Water-Based Coater is a compact, cost-efficient, and high-performance offline finishing line designed for digital print shops, small–medium commercial printers, packaging converters, and photo product makers.

This simplified configuration integrates:

Automatic Sheet Feeder

UV / Water-Based Coater (Gloss / Matte / Soft Touch / Anti-Scratch)

Automatic Stacker

Despite its compact size, this machine delivers industrial-grade coating quality, making it ideal for customers who require:

Strong adhesion

Instant surface protection

Scratch resistance

Elegant visual enhancement

Fast turnaround

Low operational cost

And works perfectly with toner, offset, inkjet, photo media, and standard packaging substrates.

Why This Compact Line?

1. Designed for 80% of Digital & Commercial Print Jobs

Most digital and commercial applications do NOT need primer:

Toner printing (Xerox / Ricoh / KM / Canon)

Offset printed sheets

Low-absorbency inkjet prints

RC photo paper & cast-coated sheets

Standard packaging boards

A single UV/WB coater provides excellent adhesion & finish.

Ideal for:

Daily print shop jobs

Tight-space environments

High-mix / low-volume work

Lower investment budgets

Quick commercial print turnaround

One coater solves the majority of commercial finishing tasks.

2. Lower Cost, Higher Productivity

Compared with dual-coating long lines:

Lower investment

Lower maintenance cost

Simpler workflow

Higher throughput for standard jobs

You still get professional grades of:

✔ High-gloss UV

✔ Matte UV

✔ Soft-touch coating

✔ Water-based coating

✔ Anti-scratch coating

3. Ideal for Most Commercial Applications

The compact line excels in:

Brochures

Catalogs

Flyers

Book covers

Rigid box surface coating

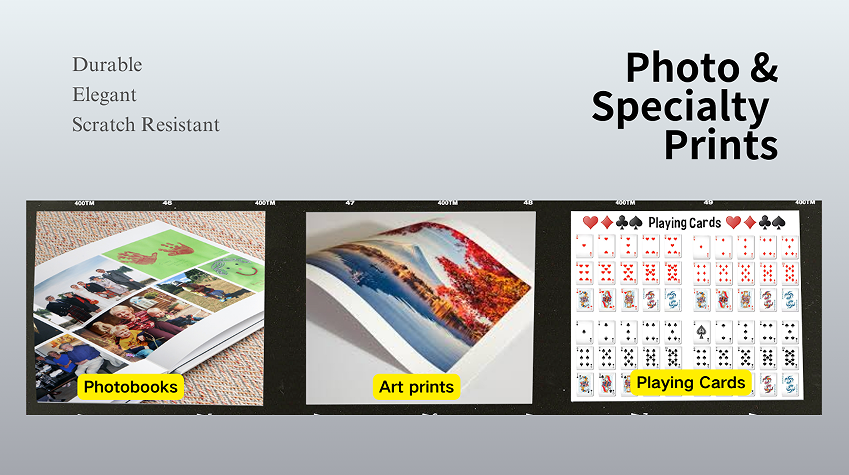

Photo books

Art prints (non-absorbent types)

Playing cards (UV version)

Menu boards

Labels (sheet format)

If the material is not highly absorbent → short line is perfect.

4. Easy Offline Integration with Any Printer

Compatible with:

Xerox / Ricoh / Konica Minolta / Canon Digital Presses

Offset printing presses

Epson / Canon / HP inkjet printers

Photo printers

Label sheet printers

No electrical or structural integration required → just feed → coat → stack.

Key Features & Advantages

1. Professional Coating Quality

Smooth high-gloss finish

Elegant matte surface

Deep black enhancement

Anti-scratch protection

Soft-touch premium effect

Consistent film thickness

Roller system:

Large-diameter rollers, micrometer adjustment, doctor roller design → uniform coating from first sheet to last.

2. UV or/and Water-Based – Choose What You Need

UV Coating:

Instant curing

High gloss

Strong scratch resistance

Ideal for toner & digital prints

Water-Based Coating:

Eco-friendly

Lower cost

Suitable for packaging and photo prints

For heavily absorbent substrates requiring primer, upgrade to long-line configuration.

3. Compact Footprint, High Productivity

Up to 25 m/min

Stable automatic feeder

Smooth stacking without marks

Fast job changeover

Operators love the simplicity

Perfect for small & medium print environments.

4. Optional LED-UV for Heat-Sensitive Media

For synthetic sheets, PVC, PET, and thin materials → LED-UV solves heat warping while delivering perfect results.

5. Lower Cost Than Lamination Film

No film inventory

No edge trimming waste

Lower operating cost

Environment-friendly option

Technical Specifications

| Module | Function | Key Features |

|---|---|---|

| Automatic Feeder | Sheet feeding | 100–500gsm, anti-double-sheet option |

| UV/WB Coater | Final coating | Gloss / matte / soft-touch / anti-scratch |

| Roller System | Coating uniformity | Large rollers, micrometer adjustment |

| Drying System | UV or LED-UV | Instant curing |

| Stacker | Delivery | Neat stacking, continuous running |

| Speed | — | Up to 25 m/min |

| Max Sheet Width | — | 650mm (custom 760mm available) |

Recommended Applications

Digital Printing (Toner)

Eliminates scratches

Enhances color and gloss

Ideal for daily print shop work

Commercial Printing

Catalogs

Brochures

Book covers

Photo & Art Prints

RC photo paper

Cast-coated sheets

Light Packaging

Folding cartons

Rigid box surfaces

Playing Cards

High-durability matte finish

No orange peel

Why Choose Double100?

✔ 25+ years coating system expertise

✔ One-stop solution (equipment + coating liquids)

✔ Professional testing available

✔ Global customers in 100+ countries

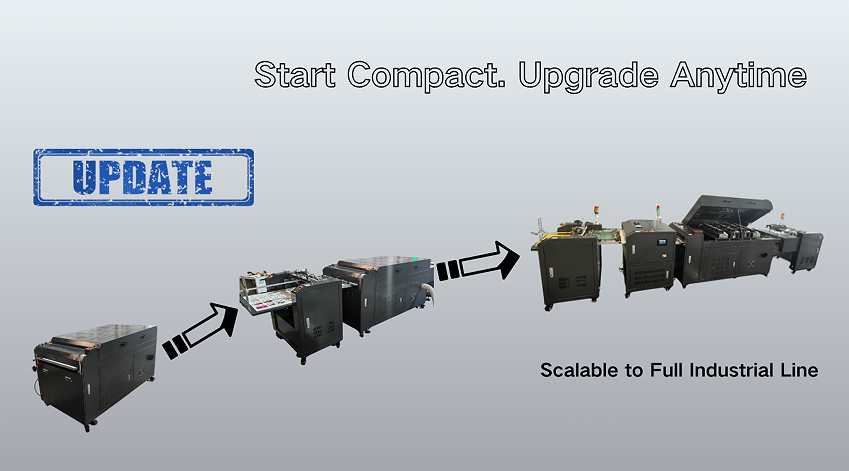

✔ Scalable system—upgrade to long-line anytime

This short-line system becomes the foundation for your future:

👉 Feeder + IR Primer Coater + UV/WB Top Coater + Stacker

Customers can start small and expand later.

Turn Your Print Finishing Into a Profit Center

Double100 offers:

Free sample testing

Layout design

Custom coating liquid recommendations

Fast lead times

Scalable configuration

👉 Get a Quote | Request Samples | Book a Video Demo

Related News

Submitted successfully

We will contact you as soon as possible