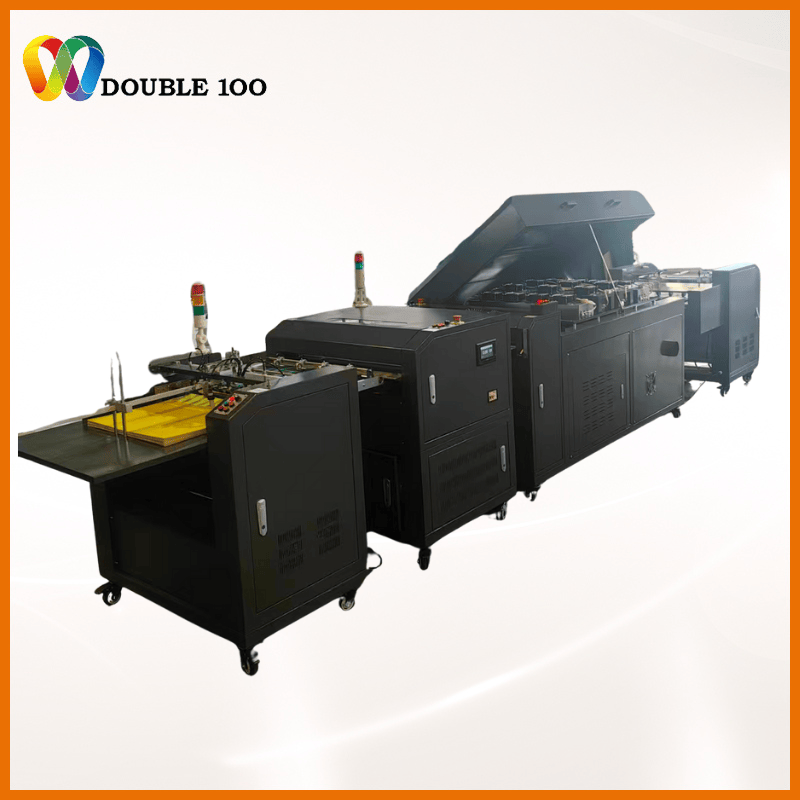

Sheet-Fed UV/IR Coating Line with Feeder & Stacker (Dual-Coater System)

Dual-Coater System: IR Primer + UV/WB Top Coating

Designed for digital prints, absorbent papers and difficult substrates to ensure perfect adhesion and smooth finishing.Complete Automatic Line

Feeder → IR Coater → UV/WB Top Coater → Stacker for continuous, stable, high-speed production.Universal Print Compatibility

Works with Toner, Indigo, Offset, Inkjet, and specialty prints—ideal for modern print shops.Premium Surface Effects

Gloss, matte, soft-touch, waterproof, anti-scratch finishing in one integrated system.Modular & Scalable Design

IR tunnels, UV lamps, hot-air dryers, and corona units can be added based on customer materials and budgets.Perfect for Multi-Industry Applications

Photo & fine art printing, commercial printing, packaging boxes, playing cards, labels, and coated boards.

Sheet-Fed UV/IR Coating Line for Professional Print Finishing Line System

High-Efficiency Offline Coating System: Feeder + IR Coater + UV/Water-Based Top Coater + Stacker

Overview — One Integrated Coating Line for Multiple Applications

The Double100 Sheet-Fed UV/IR Coating Line is an advanced offline finishing system. Designed for small and medium printing factories, digital print shops, and light industrial packaging converters, this line provides professional-grade surface protection, gloss enhancement, and material compatibility across the widest range of applications.

Built with a fully modular architecture, The line integrates:

Automatic Feeder (high-speed feeding for 100–500gsm sheets)

IR Coater (ideal for water-based primer, absorbent materials, and surfaces needing enhanced adhesion)

UV / Water-Based Top Coater (high-gloss, matte, anti-scratch, soft-touch finishing)

Automatic Stacker (smooth receiving for continuous production)

This coating line provides a comprehensive solution for printers who require strong adhesion, anti-scratch durability, visual enhancement, and cost-efficient finishing.

Why Choose a Two-Stage Coating Line?

1. Perfect for Difficult or Absorbent Materials (Paper Cups, Food Boxes, Inkjet Prints)

Many materials absorb liquid coatings → causing orange peel or uneven gloss.

A two-step process solves this:

Step 1: IR Coating (Water-Based Primer)

Improves surface uniformity

Increases adhesion

Prevents excessive absorption

Step 2: UV / WB Top Coating

Creates gloss or matte finish

Provides scratch resistance

Ensures long-term protection

This structure gives premium finishing quality beyond single-coater systems.

2. Ideal for High-Value Applications

Digital printing (toner, HP Indigo)

Premium commercial brochures

Luxury packaging & rigid boxes

Photo books / wedding albums

Food packaging (pizza boxes, paper cups)*

Specialty inkjet prints

Coated playing cards, trading cards

* Water-based primer & food-safe topcoat optional in future expansion.

3. Flexible Coating Options (All in One Line)

Water-Based Primer Coating

UV Varnish Coating (Gloss / Matte)

Anti-Scratch Coating

Soft-Touch / Velvet Coating

IR Drying Module

Optional Corona Unit for Digital Print Adhesion

You can upgrade modules at any time.

Key Advantages of the Double100 Sheet-Fed UV/IR Coating Line

1. Wide Material Compatibility

Coats 100–500gsm papers, photographic sheets, inkjet papers, digital printing sheets, packaging boards.

Art paper, offset paper

Coated & uncoated paper

Kraft paper

Food-grade packaging board

Playing card paper

Photo paper, RC, cast-coated

Digital print media

PVC sheets, KT boards (light applications)

Banner materials (selected)

Synthetic paper

2. Superior Adhesion Performance

Primer + UV system solves adhesion issues on:

Toner print

Indigo electroink

Inkjet

Specialty coated papers

3. High-Speed Production

Up to 25m/min

Continuous feeding & stacking

Less downtime, higher output

4. Cost-Efficient Coating

Compared with lamination film:

No film waste

Lower per-sheet cost

More environmentally friendly

5. Offline Integration with Any Printer

Compatible with:

Xerox

Ricoh

Konica Minolta

Canon

HP Indigo

Offset presses

Inkjet printers

6. Modular Architecture (Scalable & Future-Proof)

Each module can be sold separately or combined as a full line:

Automatic Feeder

IR Coating Unit (Water-based Primer)

UV / IR Coating Unit (Topcoat)

Dual Coating (primer + UV)

Extended Dryer Zones (60–100 cm)

Dual-deck UV lamps

Stacker / Delivery Table

Technical Specifications

| Module | Function | Key Features |

|---|---|---|

| Automatic Feeder | Sheet feeding | 100–500gsm, accurate alignment |

| IR Coater | Primer / water-based coating | IR drying, smooth coating for absorbent media |

| UV/WB Coater | Final finishing | Gloss/matte/anti-scratch/soft-touch |

| Drying System | IR or UV | Customizable drying length (600–1000mm) |

| Automatic Stacker | Receiving | Neat stacking for continuous production |

| Speed | — | Up to 25m/min |

| Max Sheet Size | — | 650mm width (custom sizes available) |

Product Details

Automatic Feeder

Vacuum-suction feeding

Suitable for thin & thick substrates

Anti-double sheet detection

For high-volume, stable production

IR Coating Unit (Water-Based Primer)

Used for:

Absorbent paper

Food packaging

Fine art

Kraft

Digital print pre-coating

Features:

Quick-dry IR lamps

Optional extended dryer section (60–100 cm)

Anti-curl airflow design

Supports low-odor, food-grade primers

3. UV Coating Unit (Topcoat)

Supports:

High-gloss

Matte

Soft-touch

Anti-scratch

Thick-film “crystal” UV (for decorative boards)

Drying options:

Standard UV

LED-UV (for heat-sensitive substrates)

Roller system:

Large-diameter rollers for stable heavy coatings

Micrometer adjustment

Anti-ghosting design

Delivery / Stacker

Jogging

Smooth stacking

Suitable for thin and thick sheets

Recommended Applications

✔ Digital Printing (Toner & Indigo)

Strong adhesion + scratch resistance

✔ Packaging & Commercial Printing

Brochures, catalogs, luxury boxes

✔ Photo & Fine Art

High-gloss & tactile finishes

✔ Inkjet Media

Primer layer eliminates absorption issues

✔ Food Box Coating (Water-Based Primer)

Pizza boxes, paper cups, food containers (regional restrictions apply)

✔Playing Cards & Game Cards

Durable matte coating with no orange peel

Ready to Build Your Coating Line?

Contact Double100 for custom configurations, coating tests, and full production line solutions.

Get Free Samples · Get Layout Design · Get a Fast Quote

Related News

Submitted successfully

We will contact you as soon as possible