Customized PRO Automatic UV coating machine Achieves Outstanding Results in Customer Acceptance Test

Qihe, China — A customer visited our manufacturing facility this week to conduct the acceptance test for his customized PRO automatic UV coating machine. Bringing both UV and water-based coating materials, the client carried out a full series of live production tests. All results met — and in several cases exceeded — the customer’s expectations.

High-End PRO Series: Engineered for Professional UV & Water-Based Coating

The machine belongs to our high-performance PRO Series, designed for the global premium market and widely applied in UV curing, UV varnishing, and water-based coating workflows. Key system features include:

·High-precision double-sheet detection

·Modular design for flexible integration

·Adjustable UV/IR lamp power

·Automated protection functions

·Stable high-speed performance

The equipment was fully assembled, calibrated, and pre-tested ahead of schedule to ensure the acceptance process was seamless.

Comprehensive Material Testing with Customer-Supplied Media

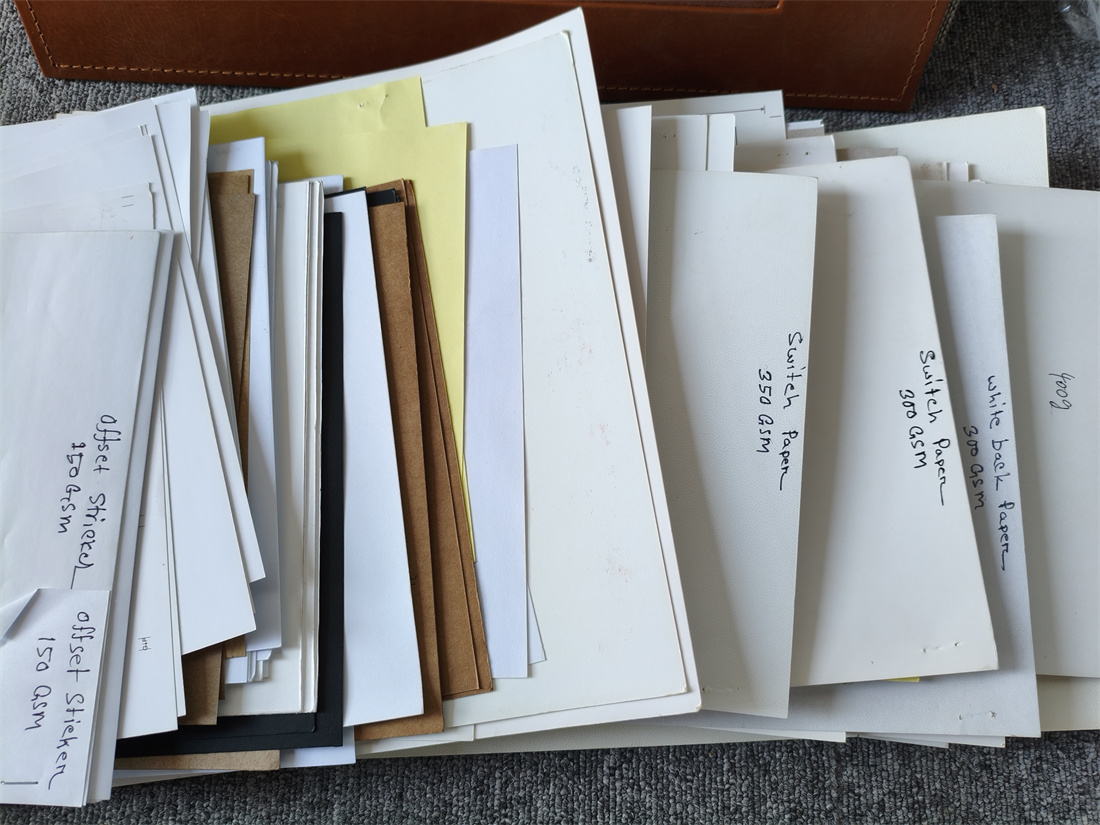

The customer brought a diverse range of materials from 150g to 400g, including adhesive sticker media, coated paper, art paper, Swedish board, and specialty substrates.

Testing followed a structured sequence:

1.UV varnish coating test

2.Water-based coating test using our compatible water based coating machine setup

3.Hybrid coating test (water-based + UV)

Across all tests, the machine delivered smooth surface results, uniform coating layers, and excellent curing quality. Different paper types responded well, and the customer expressed strong satisfaction with the overall performance.

Hands-On Operational Training

Our engineering team conducted a complete training program covering:

·Installation and power connection

·Corona treater parameter setup

·Explanation of each function button and control interface

A full workflow demonstration was provided — from feeding to corona treatment, coating, curing, and stacking.

The customer also customized a pattern roller, and our team performed a live installation and pattern coating demonstration, enabling the client to understand real production behavior.

The customer commented that the PRO model was much easier to operate compared with machines he previously used, noting its intuitive controls and user-friendly design.

Customer Feedback and On-the-Spot Improvements

The visiting customer offered valuable suggestions for optimizing the machine in long-term production:

1. Adding adjustable foot stands to improve installation flexibility

2.Integrating a counter for better control when connecting to a fully automatic production line

We welcomed the feedback and prepared engineering solutions the same day. The requested improvements were completed the next day, ensuring the machine fully aligned with the customer’s workflow requirements.

Conclusion

The successful acceptance test once again demonstrates the stability, adaptability, and high-quality performance of our PRO Series in both UV and water-based coating applications. We remain committed to providing professional, reliable coating solutions and look forward to welcoming more customers for on-site testing and technical support.