Photobook Layflat Binding Machine

All-in-One Efficiency: Multiple production steps integrated into one machine.

Future-Proof Investment: Industrial construction ensures stable 24H performance for decades.

Beginner-Friendly: 30-minute learning curve boosts factory productivity.

Versatile Production: Suitable for both low-volume and mid-volume photobook workflows.

Professional Layflat Quality: Perfect alignment, strong bonding, and 180° flat opening.

Factory-Direct Support & Warranty:24/7 technical assistance + full spare parts guarantee, backed by Double100’s real photobook factory.Three-year warranty ensures long-term peace of mind.

Album Master All-in-One Photobook Binding Machine

Professional Layflat Album Making · Creasing · Binding · Alignment · Pressing · Cutting

The Album Master All-in-One Photobook Binding Machine is a complete and professional solution designed for producing high-quality layflat photobooks, wedding albums, kids books, and premium photo books.

It combines all essential post-press functions—creasing, (hot & cold) binding, alignment, (hot & cold) pressing, powerful cutting, and hard-cover integration—into one compact, heavy-duty system.

Unlike traditional “insert album” machines, Album Master is optimized for modern layflat photobook production, enabling print shops and photo labs to upgrade to higher-value products with better margins.

Integrated Functions (Complete Post-Press Workflow)

Album Master replaces multiple machines with a single unified system:

1. High-Precision Creasing Machine

Deep, clean creases

No cracking

Suitable for laminated photo paper and PVC sheets

2. Hot and Cold Binding System

PSA (pressure-sensitive) compatible

Hot-melt EVA compatible

Hybrid workflows supported

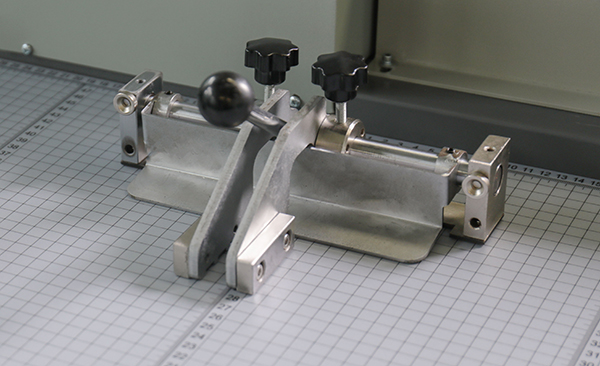

3. Accurate Alignment System

Ensures perfect page-to-page positioning

No shifting or misalignment

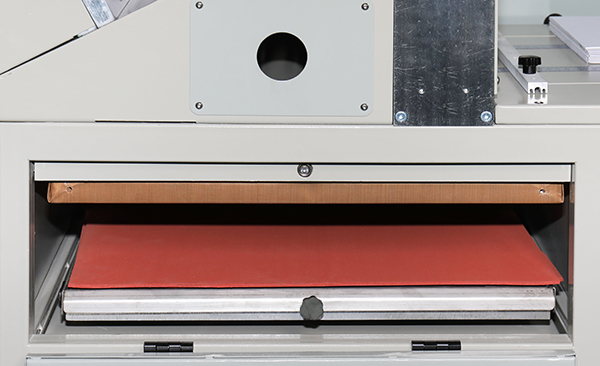

4. Hot and Cold Pressing System

Strong bonding

Perfect layflat finish

Smooth page opening

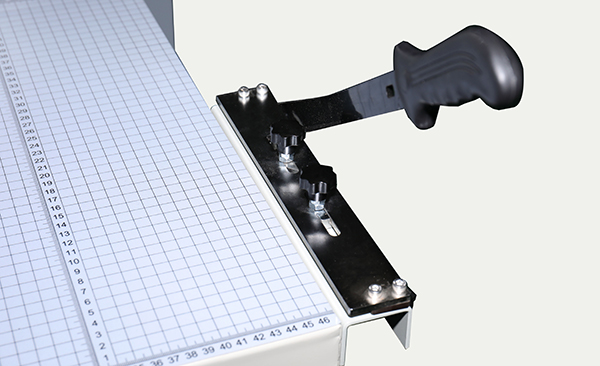

5. Powerful Cutter for PVC & Thick Blocks

Specially engineered for PVC and thick glued blocks

Clean cutting without melting or dragging

A unique advantage over ordinary album machines

6. Hard Cover Compatibility

Seamless integration with hard cover production lines

Suitable for high-end wedding albums

7. Round Corner Decoration

Adds professional finishing for premium-level albums

Key Advantages

Heavy-Duty Industrial Metal Frame

Built for 24-hour factory production with long-term stability.

Compact Size Fits Through an 80 cm Doorway

A rare advantage in this industry—ideal for small workshops.

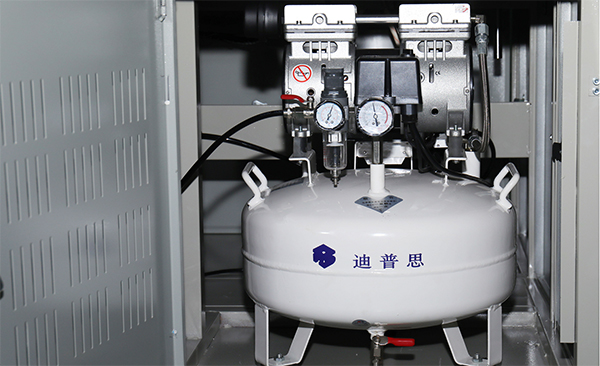

Pneumatic Even-Pressure System

Guarantees perfect flatness, zero cracking, zero shifting, and strong bonding.

Dual-Process Compatibility

One machine supports both PSA and hot-melt photobook binding workflows.

30-Minute Learning Curve

Ergonomic design allows fast training—perfect for factories with high labor turnover.

European-Standard Quality Engineering

Built based on photobook finishing logic, not low-cost machine logic.

Tested in a Real 24H Photobook Factory

Double100 is one of the few manufacturers with its own full-scale photobook factory.

Product Parameter:

Specifications | |

Mode | ALBUM MASTER 4900 |

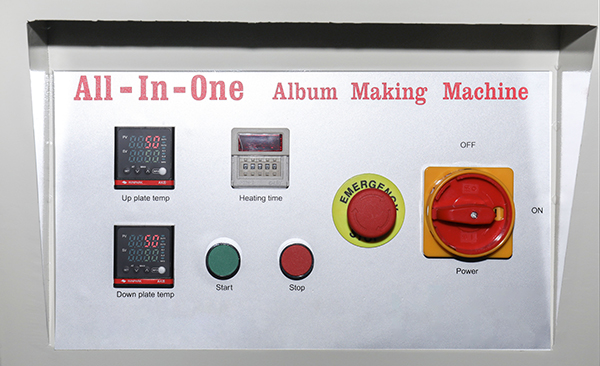

Operation principle | Electric and pneumatic |

Max size of album | 18*18inch(48*96cm) |

Cutting height | 7cm |

Paper cutting mode | |

Cutting size | 49*49*7cm |

Pressing | cold/hot |

Pressing size | 40*50*10cm |

Pressing height | 20cm |

Max. hot pressing temperature | 150 degree |

Grooving size of cover | A8cm |

Grooving blade width | 2mm |

Max size of binding | 48cm |

Max height of binding | 5cm |

Max size of cover making | 18 inch |

Comer cutter | R3-r10 too choose one |

Voltage | 220v/60hz/50hz/3.5kw |

Weight(N.W/G.W) | 450kg/480kg |

Machine size | 1.5*1.06*1. 42m |

Packaga size | 1.6*1.16*1.52 |

Other Models | J-5,ST-6Z,ST-7S,DT-4S,J-5,P-2 allin one album |

Production Capacity

15--25 books per hour

Suitable for small to medium photobook factories

Stable long-shift operation

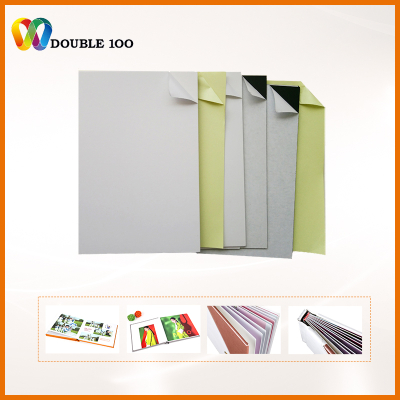

Compatible With Full Production Ecosystem

The machine integrates perfectly with Double100’s full photobook production line:

PVC inner sheet production

Hard cover maker

UV coating / lamination

Album Cover, Box, Frame

ERP production and ordering software

This allows customers to build a complete layflat photobook production factory with one supplier.

Product Details and Characteristics:

Our Advantage

·Main Characteristics·

| The machine is of slide binding, making it easyfor operator, and the magnetic is very helpfulfor the book position. lmm panel ensure thealbum open totally fat |

The creasing part with the whole facemeasurement and strong magnetic ruller ensuring correct creasing |  |

| Wheels for adjusting the material thickness,coating thickness and doctor blade to ensure themachine workingin a perfect condition |

High precise album cutter is speciallydesigned for cutting album which maymade by PVC or glued cardboard.With IR ray to ensure the safety of theoperato |  |

| The machine can work with both hotmelt sheets and self adhesive sheets.The pressing power is big and ensurableAnd Big control panel |

The side table can work as a working tableor is used to make hard corver. lt include allthe functlons for making hard cover: centrapositlon , photo comer trimming |  |

| High volumn silent air compressoris equippment inside the machine,offering sustainable air supply |

The heavy duty round corner cutter,ensuring the comer was cut smoothly |  |

Why Choose Double100?

27+ years in photobook equipment manufacturing

One of the earliest layflat photobook solution developers

More than 100 countries served

Over 200 patents

Real 24H photobook factory for continuous testing

Full production line integration: machines + materials + software

What Is a Layflat Photobook?

Layflat photobooks are becoming the global standard for wedding albums and professional photo books.

Compared with traditional insert-page albums, layflat photobooks offer:True 180° panoramic spreads

Continuous images without page breaks

Strong bonding and long-term durability

Higher perceived value

Higher retail profit

Compatibility with PVC and laminated sheets

Album Master helps factories transform from low-value insert albums to high-end layflat photobook production without complicated machinery.

Application:

About Double100 — The Global Powerhouse Behind Photobook Production Lines

Founded in 1997, Double100 is one of the world’s earliest and most influential innovators in layflat photobook production technology.

For more than 27 years, we have built a complete ecosystem that includes:

✔ Professional Photobook Machines

✔ PVC Inner Sheets

✔ Hard Covers & Frames

✔ UV Coating & Lamination

✔ ERP & Online Ordering Software

✔ Full Factory Setup & Technical Training

Unlike typical equipment suppliers, Double100 operates its own 24-hour photobook factory, allowing every machine to be tested under real production conditions.

This gives us a level of stability, precision, and reliability unmatched in the industry.

Today, Double100 delivers solutions to more than 100 countries, supported by 20+ global agents, and trusted by leading brands including Fujifilm, Lucky, HP, Canon, Konica Minolta, Epson, and world-class photobook labs.

With 200+ patents, a full R&D center, international certifications (CE/ISO), and a complete material + machine + software ecosystem, Double100 is the only manufacturer in the world capable of delivering a full photobook factory from zero to production.

From a single machine to a complete production line —

Double100 powers the global photobook industry with precision, stability, and long-term value.

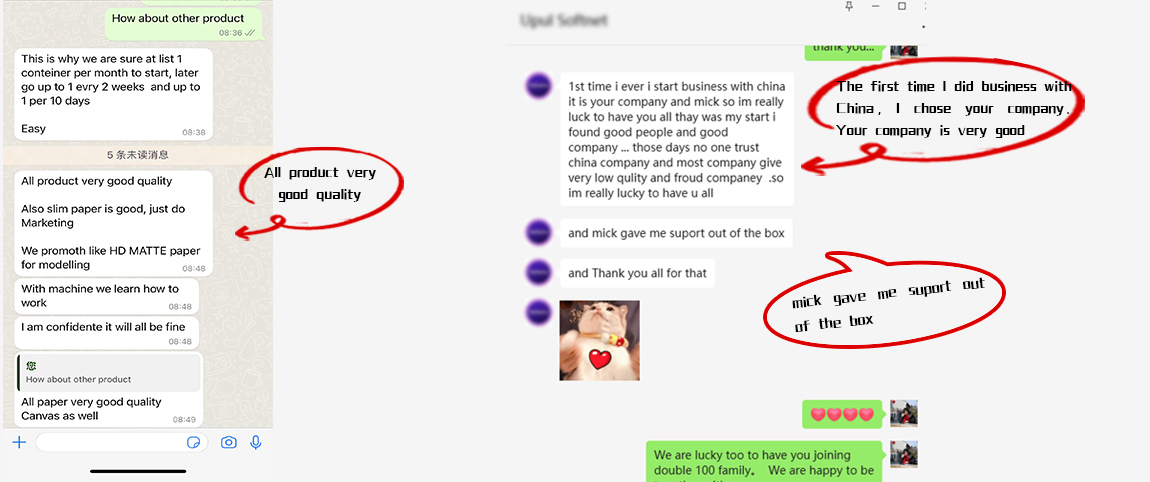

Customer Feedback:

Double 100 specializes in advanced coating solutions, precisely engineered to improve the quality and durability of your printed materials. Discover our extensive range of coating machines designed to meet every aspect of your print finishing requirements across diverse industries.

Post-Print Enhancement:UV and aqueous coating machines for paper prints, labels, stickers, corrugated cardboard, large-format materials (such as banners), and boards. These coatings enhance color vibrancy, provide protection against wear and tear, and make surfaces waterproof and resistant to sunlight.

Pre-Print Preparation: Primer coating machines are designed to prepare surfaces of paper prints and ceramics, enhancing image quality, providing water and scratch resistance, and extending product longevity. As manufacturers, we are actively seeking distributors worldwide to introduce our innovative solutions to new markets.

Company Strength:

Innovative Printing Solutions

Welcome to Jinan Cmall International Trading Co., Ltd, your trusted partner in advanced printing technologies. We are proud to represent Double 100, a renowned leader in lay-flat photo book machines, glued PVC sheets, and UV coating machines. With over 20 years of industry experience, our commitment to quality and innovation truly sets us apart.

Comprehensive Product Range

Double 100 provides a full spectrum of printing and packaging solutions, from manual to fully automatic machines. Our lineup includes lay-flat photo book machines, hardcover makers, and a variety of coating machines, all crafted to meet stringent quality standards. For added peace of mind, we back all products with a 3-year warranty.

Global Reach & Reliability

With partnerships in over 90 countries, Cmall International collaborates with industry leaders such as HP Indigo, Canon, and Konica Minolta. Our competitive pricing, tailored solutions, and exceptional reliability make us the top choice for print shops worldwide. Partner with us to enjoy seamless, high-quality service for all your printing needs.

Client Positive Feedback:

Related News

Submitted successfully

We will contact you as soon as possible