Hot Glue Machine

HT8 gluing machine

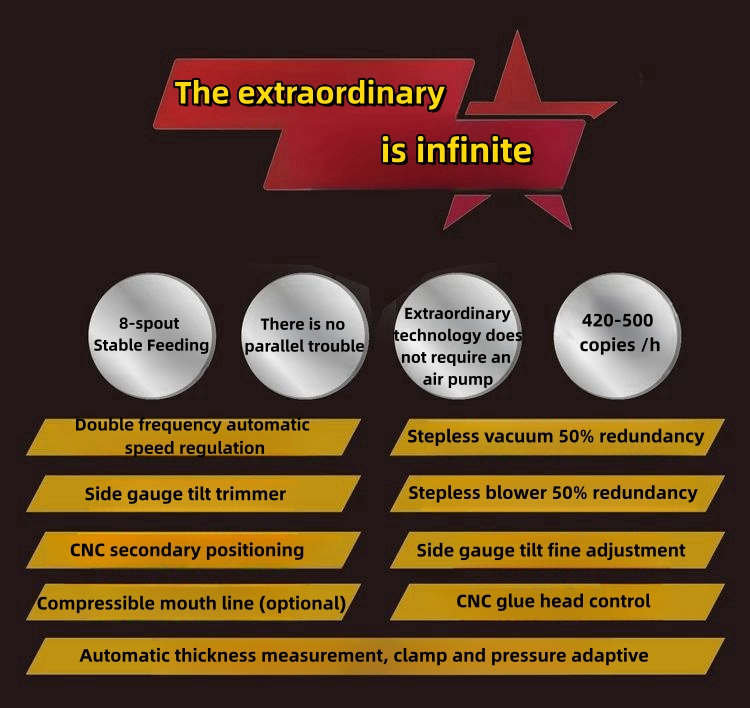

1. Dual-frequency conversion technology: Automatic speed regulation adapts to different book thicknesses,

improving work efficiency.

2. Side guide tilt fine-tuning: Precise adjustment ensures binding quality.

3. CNC secondary positioning: Accurate positioning enhances binding precision.

4. Stepless vacuum and blowing redundancy: Enhances binding stability, suitable for various paper types.

5. Intelligent control and color touchscreen: Intuitive operation, convenient management.

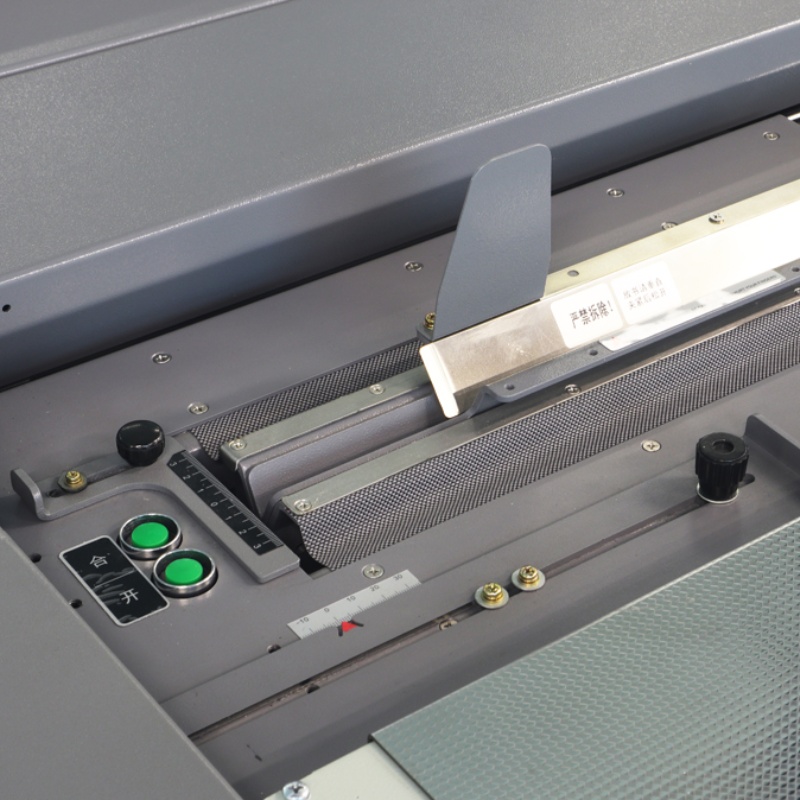

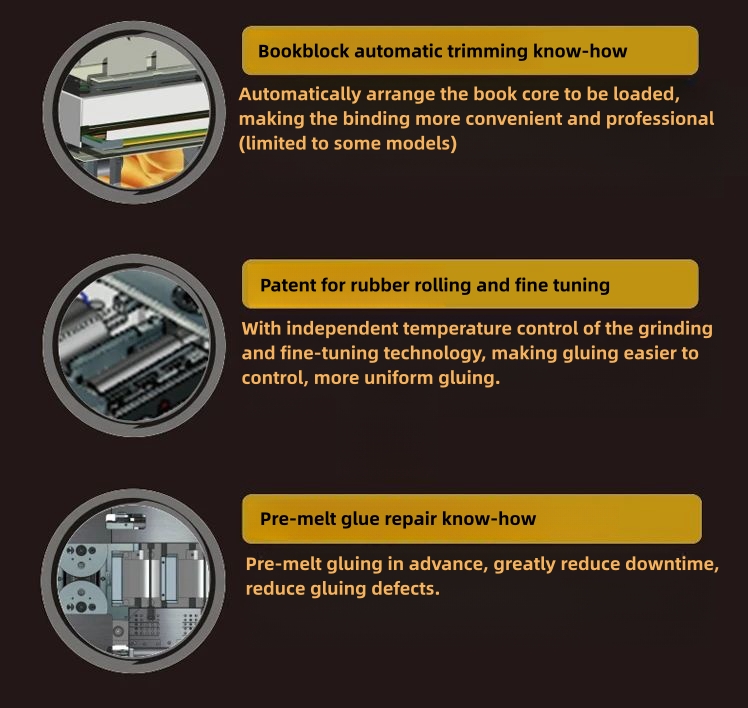

6. Proprietary technologies: Such as the sun knife and automatic book block alignment, enhance professional binding.

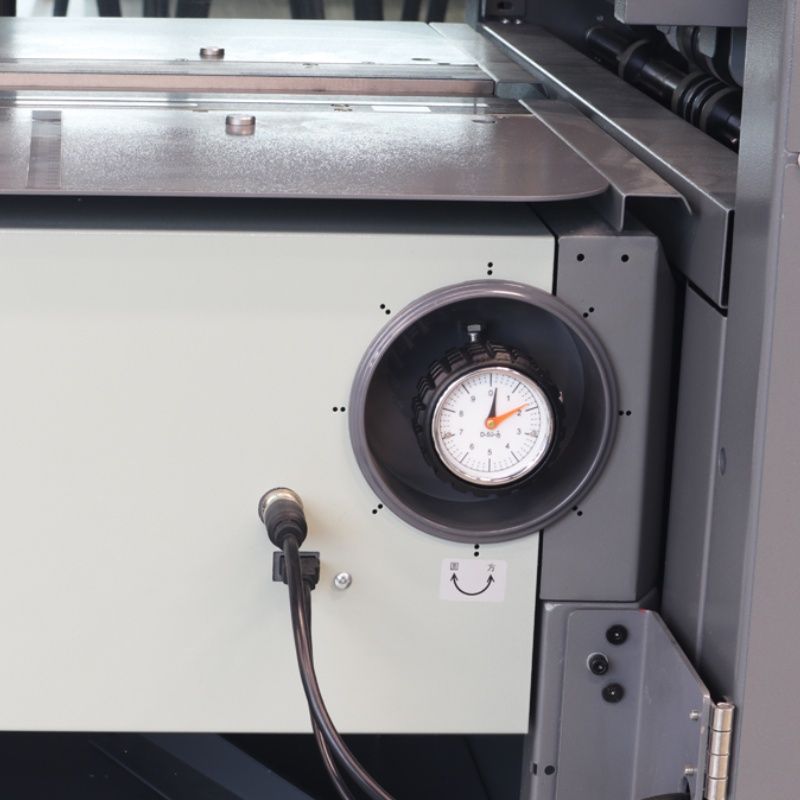

7. Patent for glue rolling fine-tuning: Even glue application, easy control.

8. Eco-friendly design: Intelligent smoke extraction, protects the working environment.

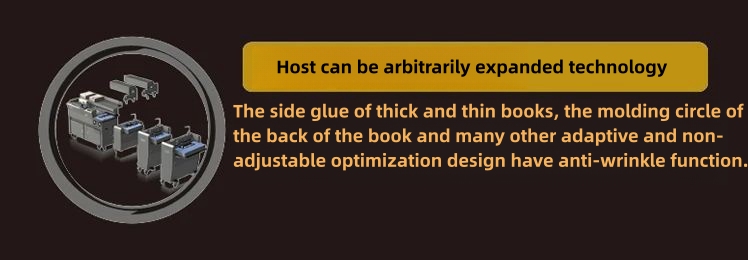

9. Modular design: Easy to expand, meets future development needs.

10. Vertical clamping technology: Anti-wrinkle feature, adapts to different book thicknesses.

11. Thick and thin book adaptive technology: Optimization design for hassle-free adjustment, improves

binding efficiency.

The Double100 HT series perfect binders (including models HT5, HT6, HT7, HT8, HT9) are a range of high-performance binding machines characterized by the following features:

1. User-Friendly Operation: The Double100 machine features a 7-inch color touch screen, providing an intuitive interface that simplifies operation and boosts work efficiency.

2. Precise Control: The responsive touch screen enables quick and accurate adjustments of binding parameters, reducing operational errors and ensuring consistent results.

3. Streamlined Interface: The newly designed interface is easy to navigate, allowing even first-time users to quickly master the machine, cutting down on training time.

4. Efficient Milling Motor: Equipped with a high-power milling motor, the machine efficiently mills the spine and creates notches, ensuring a strong, secure bind and enhancing binding speed.

5. High-Quality Binding Results: The sun blade technology used for spine milling guarantees an even distribution of notches, resulting in a stronger and more reliable bind.

6. Dual Glue Wheel System: The dual glue wheel system optimizes the binding process, with the main glue wheel ensuring even application and the hot glue wheel smoothing the glue layer to minimize stringing and create a more polished, aesthetically pleasing bind.

In summary, the Double100 HT series perfect binders excel in enhancing work efficiency, ensuring binding quality, simplifying the operation process, and improving binding outcomes, making them suitable for high-quality document binding requirements.

Main Characteristics:

1. Touchscreen Operation: The 7-inch color touchscreen offers an intuitive, user-friendly interface, making it easy for operators to manage settings and improve efficiency.

2. Precise Control: The touch-sensitive screen allows for quick and accurate adjustments to binding parameters, minimizing the risk of errors and ensuring consistent results.

3. Ease of Use: With its simplified interface, the machine allows even first-time users to quickly familiarize themselves with its operation, reducing the need for extensive training.

4. High-Efficiency Knife Motor: The high-powered knife motor mills the spine and creates precise slots, ensuring a strong bind while also increasing the binding speed.

5. High-Quality Binding Effect: Sun knife technology ensures an even distribution of slots, resulting in a more secure, uniform, and high-quality bind.

6. Dual Glue Wheel System: This system improves binding quality by ensuring consistent glue application with the main glue wheel, while the hot glue wheel smooths out the layer to minimize stringing, creating a cleaner and more polished finish.

Product Parameter:

| HT5 | HT6 | HT7 | HT8 | HT9 | |

| Bind length(mm) | 110-330 | 110-330 | 110-440 | 110-460 | 110-460 |

| Bind thickness(mm) | 1-58 | 1-58 | 1-58 | 1-58 | 1-58 |

| Block height(mm) | 130-300 | 130-300 | 130-300 | 130-300 | 130-300 |

| Speed | 300-400 book/h on-line 400book/h | 350-500 book/h on-line 500book/h | 320-400 book/h on-line 400book/h | 320-420 book/h on-line 420book/h | 350-500 book/h on-line 500book/h |

| Automatic speed change | / | √ | √ | √ | √ |

| Melt time | 35min | 35min | 35min | 35min | 40min |

| Gluing way | 3 rollers | 3 rollers | 3 rollers | 4 rollers | 4 rollers |

| Pre-melt glue | √ | √ | √ | √ | √ |

| Smoke extractor | operation | operation | operation | operation | √ |

| Display mode | 7 inch touch screen | 7 inch touch screen | 7 inch touch screen | 7 inch touch screen | 7 inch touch screen |

| Net weight of machine (kg) | 220 | 240 | 300 | 300 | 320 |

| Frequency conversion | √ | √ | √ | √ | √ |

| Power supply parameter | 2600w | 2600w | 2600w | 3200w | 3400w |

| Machine size (mm) | 1320*780*1070 | 1320*780*1070 | 1590*780*1070 | 1750*800*1050 | 1750*800*1050 |

Product advantage:

User-Friendliness: The large color touchscreen provides an intuitive and easy-to-navigate interface, allowing operators to learn and operate the machine without specialized training.

Efficient Performance: With its high-power blade motor and optimized binding process, the machine increases binding speed, making it perfect for high-volume production.

Precise Control: The touchscreen allows for precise adjustment of binding parameters, ensuring consistency and accuracy in every bind for a professional finish.

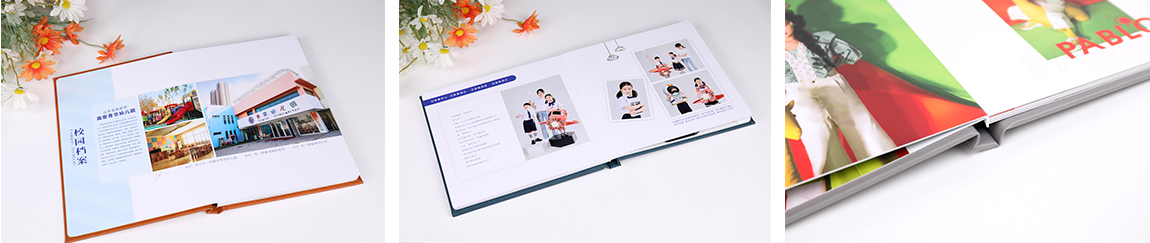

Binding Quality: Advanced milling and binding technology result in a strong, durable, and visually appealing bind that enhances the overall quality of documents.

Versatility: Capable of binding a wide range of document sizes and types, the machine offers flexibility to meet diverse binding requirements.

Durability: Built with high-quality materials and advanced manufacturing processes, the equipment ensures reliable and stable performance over the long term.

Ease of Maintenance: The machine is designed for easy maintenance, with simple cleaning and consumable replacement, minimizing downtime and keeping production running smoothly.

Cost-Saving: Its efficient binding process minimizes material waste, helping to reduce operational costs over time and increasing profitability.

Product Details and Characteristics:

Application:

Hot glue machines are essential tools across various industries, including packaging, woodworking, electronics, and textiles, providing efficient adhesive application for bonding purposes. This article delivers a detailed technical overview of hot glue machines, focusing on their engineering principles, material compatibility, regulatory compliance, and best operational practices.

What is a Hot Glue Machine?

A hot glue machine, also known as a hot melt adhesive (HMA) applicator, is a device that melts solid adhesive sticks or pellets into a liquid state, which is then dispensed onto surfaces to create a strong bond upon cooling and solidification. The system typically includes a heating unit, a melting chamber, and a dispensing mechanism.

Technical Features and Engineering Principles

Heating System

Uses electric heaters (typically cartridge or band heaters) to melt adhesive at controlled temperatures, usually between 120°C and 200°C depending on adhesive type.

Temperature control is achieved via thermocouples and PID (Proportional-Integral-Derivative) controllers to maintain consistent melting and prevent adhesive degradation.

Adhesive Types

Commonly uses thermoplastic polymers such as ethylene-vinyl acetate (EVA), polyamide, or polyurethane-based hot melts.

Viscosity and setting times vary by formulation, influencing application speed and bond strength.

Dispensing Mechanism

Includes manual trigger guns, pneumatic systems, or automated robotic nozzles for precise adhesive application.

Flow rate control enables customization for different substrate types and bond requirements.

Melting Chamber and Reservoir

Designed for continuous feeding of adhesive sticks or pellets, with agitation systems in some models to ensure uniform melting.

Materials Compatibility and Applications

Materials Bonded: Paper, cardboard, wood, plastics, textiles, metal foils, and composites.

Industries Served: Packaging, automotive, electronics, furniture manufacturing, and crafts.

Regulatory Standards and Safety Compliance

ISO 9001: Quality management systems for consistent manufacturing and operation.

CE Marking: Conformance to European safety and environmental standards.

OSHA Regulations: Workplace safety standards related to thermal equipment and chemical exposure.

RoHS Directive: Restriction of hazardous substances in electrical equipment components.

Adherence ensures safe operation, product quality, and regulatory acceptance.

Operation and Maintenance Best Practices

Temperature Management:

Set the temperature according to adhesive manufacturer specifications to avoid thermal degradation or poor bonding.

Use PID-controlled systems for stability.

Cleaning and Maintenance:

Regularly clean the nozzle and melting chamber to prevent clogs and contamination.

Inspect electrical components and heating elements for wear.

Safety Measures:

Use heat-resistant gloves and safety glasses.

Ensure proper ventilation to mitigate fumes.

Install emergency shutoffs and insulation to prevent burns.

Training:

Operators should be trained in machine use, maintenance procedures, and emergency protocols.

Frequently Asked Questions (FAQs)

Q1: What adhesives are compatible with hot glue machines?

A: EVA-based adhesives are most common, but machines can also handle polyamide, polyurethane, and specialty formulations depending on application needs.

Q2: How is the dispensing rate controlled?

A: Dispensing is regulated via manual triggers, pneumatic pressure, or programmable pumps in automated systems.

Q3: What are common issues with hot glue machines?

A: Adhesive clogging, inconsistent temperature control, and nozzle wear are typical; regular maintenance mitigates these problems.

Q4: Are hot glue bonds waterproof?

A: Some hot melt adhesives offer water resistance, but suitability depends on the adhesive formulation and application.

Conclusion and Professional Call to Action

Hot glue machines are versatile, efficient tools critical for modern manufacturing and assembly processes. Understanding their technical specifications, operational requirements, and safety standards ensures optimal performance and longevity.

We offer expert consultation, high-quality hot glue machinery, and comprehensive after-sales support to meet diverse industrial needs. Contact us today for tailored solutions that enhance your production efficiency and bonding quality.

Related News

Submitted successfully

We will contact you as soon as possible