QHS Round Corner Cutters

Product advantage:

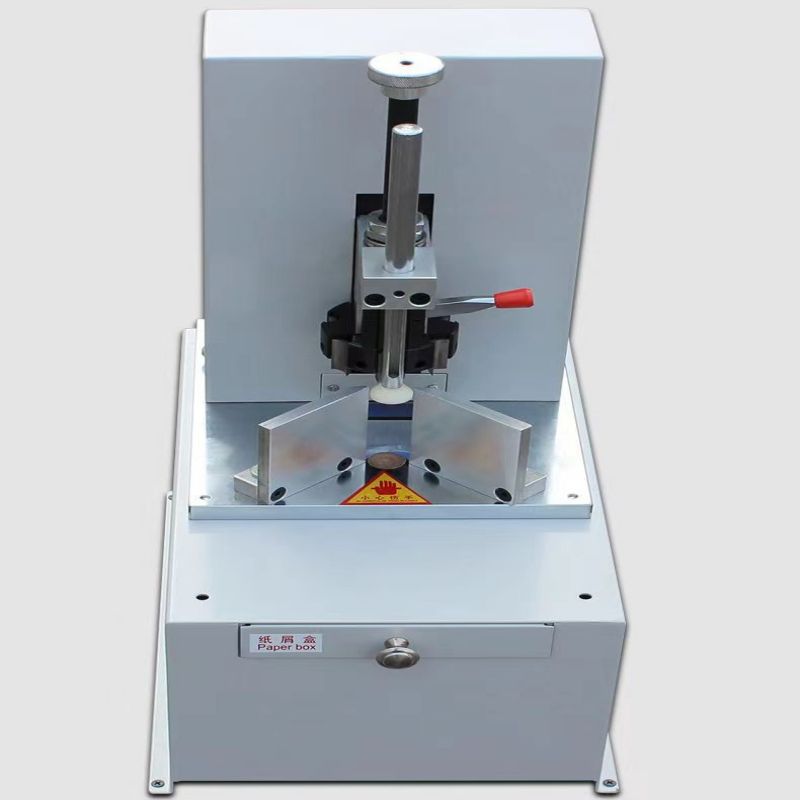

Double100 Commercial Corner Rounder Machine

Ultimate Efficiency

Cut up to 1.2 inches (30mm) thick! This powerful machine allows you to round multiple corners at once, saving you valuable time and effort.

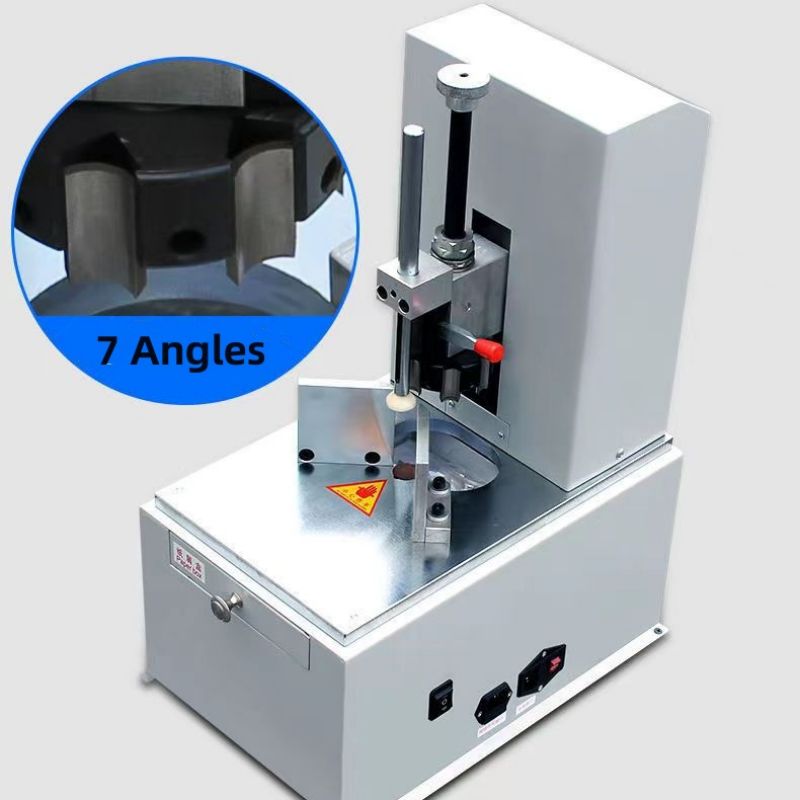

Interchangeable Cutting Dies

Includes R6mm (1/4”) and R10mm (3/8”) dies, crafted from premium carbide steel for exceptional sharpness and durability.

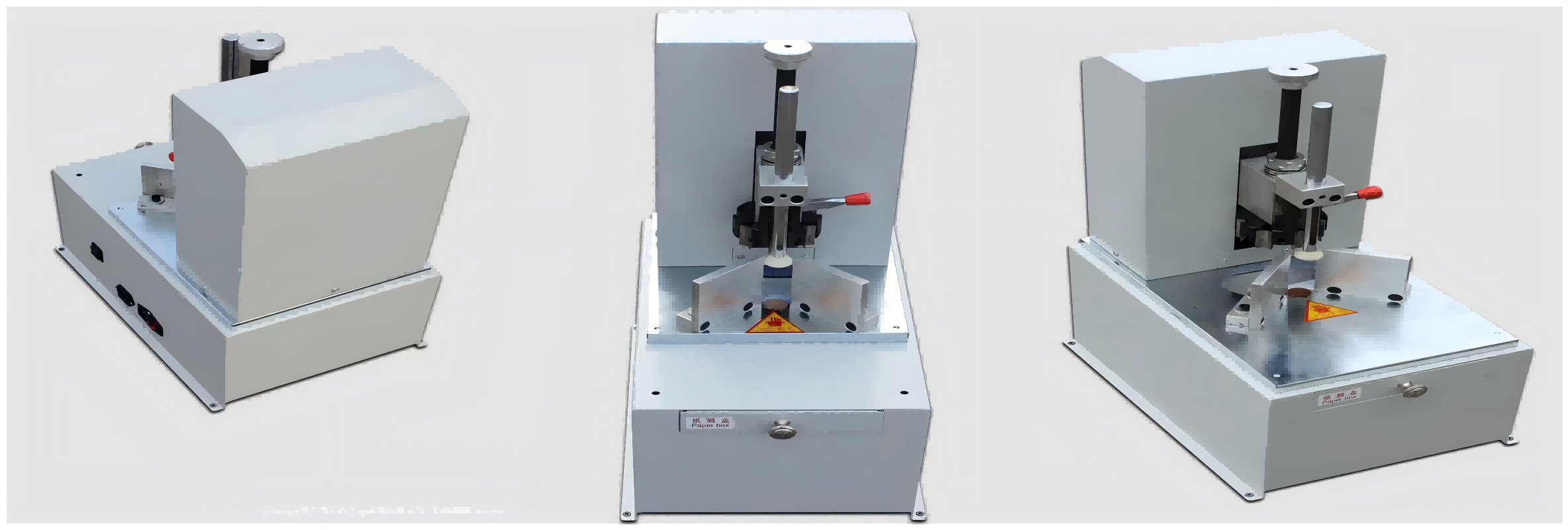

Heavy-Duty Construction

Built with a robust A3 steel body, this tabletop cutter ensures stability and safety, making your corner rounding a breeze.

User-Friendly Design

Featuring a longer handle for comfort and a paper-pressing device to prevent slips, achieving precise cuts has never been easier.

Versatile Applications

Perfect for a variety of materials—paper, cardstock, PVC, and soft metals. Ideal for rounding corners on business cards, documents, photos, and more!

QHS Round Corner Cutters

Main Characteristics:

High Cutting Capacity: Handles materials up to 50mm thick, suitable for various paper and card types.

Versatile Blades: Equipped with R3-R9 blades, offering adjustable corner radius options to meet different needs.

Efficient Cutting Speed: Performs 56 cuts per minute, ensuring fast and precise operation for increased productivity.

Durable Build: Constructed from high-quality materials for long-lasting performance

Customer Feedback:

Double 100 specialize in advanced coating solutions meticulously engineered to enhance the quality and durability of your printed materials. Explore our comprehensive range of coating machines tailored to suit every aspect of your print finishing needs across various industries:

Post-Print Enhancement: UV/aqueous coating machines for paper prints, labels, stickers, corrugated cardboard, large format materials (banner ect), and boards, corrugated cardboard, enhancing vibrancy and protecting against wear and tear, making it water-proof, sunshine resistant.

Pre-Print Preparation: Primer coating machines to prepare surfaces of paper prints, ceramics, discover how our coatings enhance print images, provide water and scratch resistance, and extend longevity.

As manufacturers, we're seeking distributors worldwide to bring our innovative solutions to new markets.

QHS Round Corner Cutters are precision tools widely used in industries requiring clean, safe, and aesthetically pleasing rounded edges on materials such as paper, plastics, leather, and metal sheets. Their importance spans manufacturing, packaging, and printing sectors where corner finishing is critical for product quality and safety compliance. This article provides a detailed, technically sound exploration of QHS Round Corner Cutters, including engineering principles, materials, operational guidelines, regulatory considerations, and maintenance practices.

1. What Are QHS Round Corner Cutters?

QHS Round Corner Cutters are specialized cutting devices designed to trim sharp edges into smooth, rounded corners. The “QHS” designation refers to a specific series or model range distinguished by precision manufacturing tolerances and ergonomic design for efficient manual or semi-automatic operation.

2. Engineering Principles and Design Features

2.1 Cutting Mechanism

Utilizes a rotary blade or fixed die with a predefined radius to remove material at the corners.

Precision sharpening ensures consistent cutting quality without fraying or tearing.

Cutting radius options commonly range from 3 mm to 25 mm, adaptable to various application needs.

2.2 Material Compatibility

Designed to cut through materials such as:

Paper and cardboard (50–500 gsm)

Plastic sheets (PVC, PET, up to 1 mm thickness)

Thin leather and textiles

Thin metal foils (subject to cutter design)

2.3 Construction Materials

Blades: High-speed steel (HSS) or tungsten carbide for durability and edge retention.

Body: Hardened steel or aluminum alloy for rigidity and lightweight handling.

Ergonomic Handles: Often coated with anti-slip materials such as rubber or thermoplastic elastomers.

3. Industry Standards and Safety Regulations

QHS Round Corner Cutters must adhere to multiple regulatory and safety standards:

ISO 9001: Ensures quality management in manufacturing.

ANSI B11.19: Safety requirements for cutting tools.

CE Marking: Compliance with EU Machinery Directive for user safety.

RoHS: Restricts hazardous substances in materials.

Operators should use appropriate personal protective equipment (PPE) such as cut-resistant gloves when handling cutters.

4. Selection Criteria: How to Choose the Right Round Corner Cutter

Material Type and Thickness: Ensure blade hardness and cutter clearance are compatible.

Corner Radius Needed: Match cutter die radius to design specifications.

Operation Mode: Manual for low volume; pneumatic or hydraulic-assisted for higher throughput.

Precision Requirements: Tolerances within ±0.1 mm are typical for industrial use.

Durability: Look for replaceable blade systems and corrosion-resistant coatings.

5. Operating Guidelines and Best Practices

Secure the material firmly on a flat surface to avoid shifting during cutting.

Align the cutter accurately with the corner to maintain consistent radius.

Apply steady, moderate pressure; excessive force may damage the blade or material.

Regularly inspect blades for sharpness; dull blades lead to rough edges.

Store cutters safely to prevent accidental injury or blade damage.

6. Maintenance and Longevity

Blade Sharpening: Depending on usage, sharpen blades every 3,000–5,000 cuts.

Cleaning: Remove debris after each use to prevent blade corrosion.

Lubrication: Apply light machine oil to moving parts in pneumatic cutters.

Replacement: Monitor blade wear and replace when quality declines.

7. Common Use Cases and Examples

Printing Industry: Creating rounded corners on business cards and brochures.

Packaging: Rounding box flaps to prevent injury during handling.

Leather Goods Manufacturing: Softening corners on wallets, belts, and bags.

Plastic Fabrication: Finishing signage or protective covers.

FAQ Section

Q1: What is the maximum thickness QHS Round Corner Cutters can handle?

A: Typically, manual cutters handle up to 1 mm for plastics and 500 gsm for paper. Heavy-duty pneumatic models can manage thicker materials.

Q2: How do I maintain cutting precision over time?

A: Regular blade sharpening, proper cleaning, and correct usage pressures maintain precision.

Q3: Are round corner cutters suitable for metal sheets?

A: Only thin metal foils; thick metal requires specialized cutting machinery.

Q4: Can I customize the corner radius?

A: Yes, many QHS cutters offer interchangeable dies or adjustable radius settings.

Conclusion and Call to Action

QHS Round Corner Cutters are essential for producing high-quality, safe, and visually appealing rounded edges across diverse materials and industries. Understanding their engineering design, material compatibility, and safety requirements ensures optimal selection and usage.

We encourage professionals to evaluate their specific operational needs carefully and invest in cutters that meet stringent quality and safety standards. For tailored recommendations, training, or procurement advice on QHS Round Corner Cutters, contact our technical experts today to enhance your production efficiency and product quality.

Related News

Submitted successfully

We will contact you as soon as possible