High Efficiency Automatic Creasing And Folding Machine

Product advantage:

1.Economic Automatic Layflat Album Making Solution

2.It can be used for Middel creasing for album inner photos and Multiple lines for soft covers

3.It can crease Max 10 Lines and make the folding

4.It works peferctly for Invitation card, catalogue, flyer, brochure ect.

5.It works with feeder and any other binding machines.

6.Factory store to ensure 24h*7 service

7.3 Years Warranty

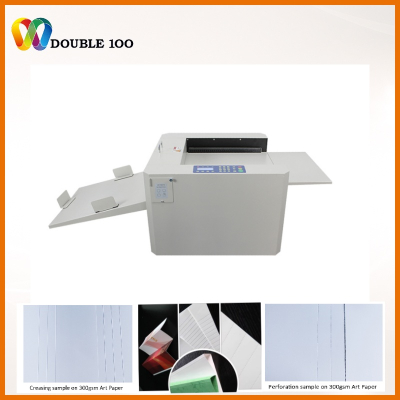

According to the characteristics of making photobook of personalized, dedicated and complex, Double 100 produced the professional automatic creasing and folding machine as the first step of making a decent photobooks.

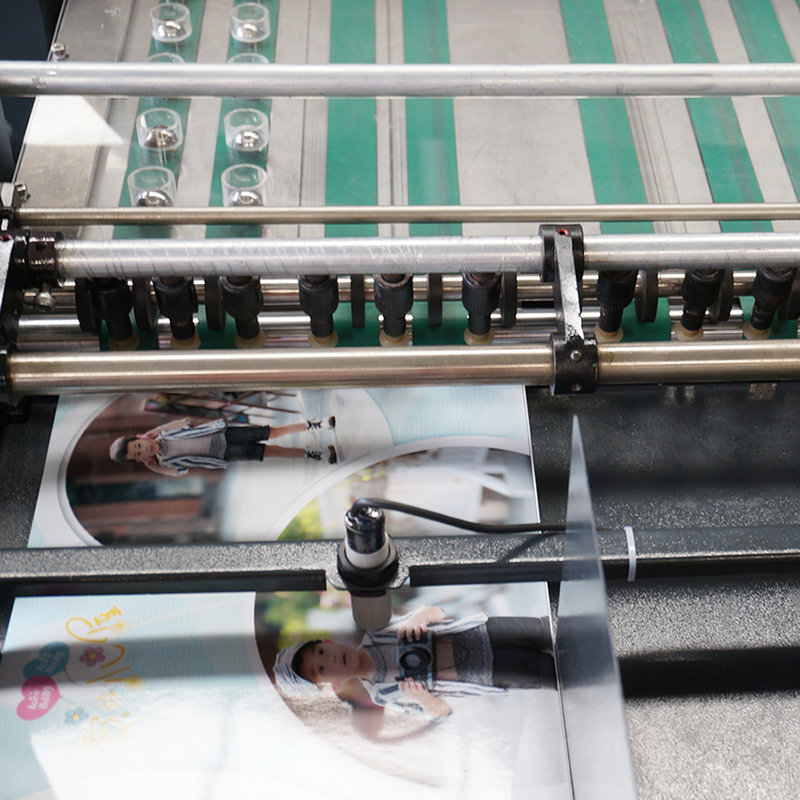

This machine consists of four main components: alignment, creasing, folding, and spine pressing. These parts work in unison to produce precisely creased and folded pages, ideal for photo albums. This versatile and efficient machine can create either a single crease and fold or multiple creases (up to 10 lines) for soft covers. Operating at a rapid speed of about one second per page, it ensures precise, clean, and adjustable creases. The adjustable pressure feature allows for perfect creasing and folding every time. Additionally, the spine pressing function produces a smooth, well-defined spine, making the binding process easy. Our automatic creasing and folding machine simplifies album production, enhances efficiency, and enables you to produce high-quality photo albums effortlessly.

Product advantage:

1. Multiple functions: A machine can perform four functions, including deviation, creasing, folding, spine pressing

2. High efficiency: 3600pc/hour! perfect creasing, fast folding, improve photo album production efficiency

3. Deviation Function: ensure the paper to go in a correct direction and help to connect with feeder directly to realize automation

4. Simple operation: PLC system, only need button control, convenient operation

5. Competitive Price: a very cpmpetitive price compared to other international brands and fully automatic album machine while even better performance!

Main Characteristics:

1. Automatic Production Lines

> low cost automatic > reduce creasing failure > efficient production process

2. Deviation Function

3. Creasing and Middle Folding Function

4. Easy PLC System

5. Precise Stopper

6. High Capacity Cylender

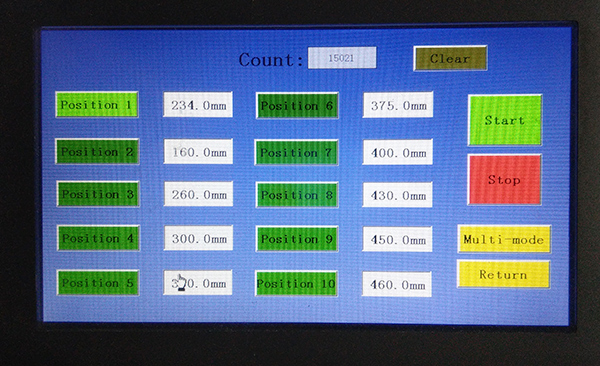

7. 10 Memory Creasing Positions

8. Spine Pressing Function

9. Easy Maintance

10. Working for soft cover Multiple creasing

Product Parameter:

Product Name | |

Dimenstion | 122*72*140cm |

Weight | 180kg |

Power | 220V/50HZ/60HZ/1000W |

Function | Diavation, Creasing And Folding |

Control System | PLC Digital Control |

Folding Speed | 1PC/Second |

Min. Working Size | 10*20cm |

Max. Working Size | 48*96cm |

Max. Paper Thickness | 400g |

Creasing Thicness Optional | 1mm for thin paper/1.5mm for thick paper |

Max. Creasing Lines | 10 Lines |

Spine Pressing | Optional |

Product Details and Characteristics:

Highlight

·The Machine Details·

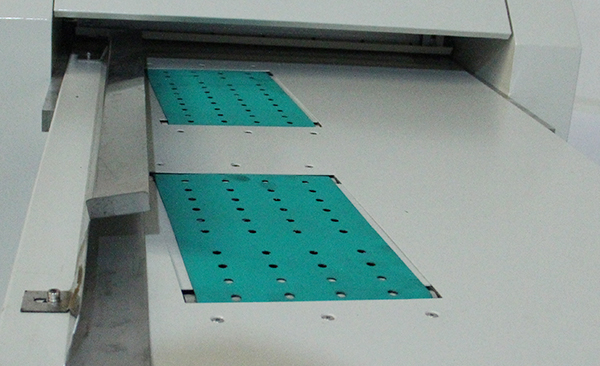

| 1. With diavation function, to ensure the paper to go in a correct direction. And helps to connect with feeder directly to realize automation. |

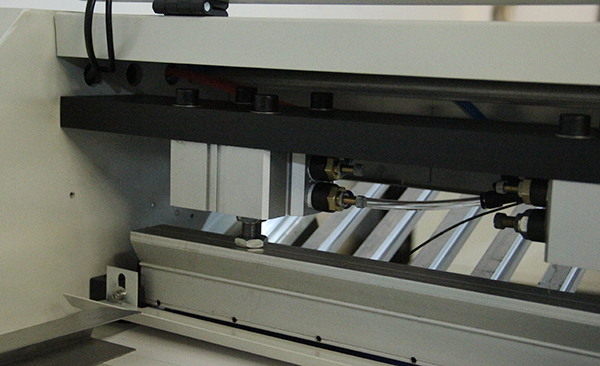

2. Inset PLC screen and easy button systematic control, the operation is quite easy. We can finish the job by one button only. |  |

| 3. The machine is composed by two main functions, creasing+folding. With creasing function we can make the lines neat and beautiful |

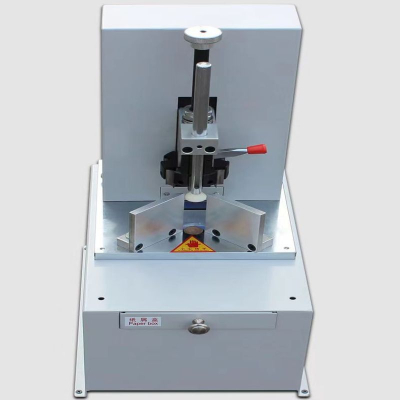

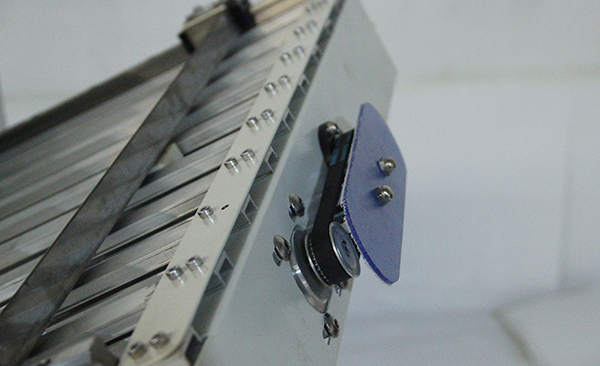

4. The high precisely and heavy duty stopper helps the paper stop in a correct way |  |

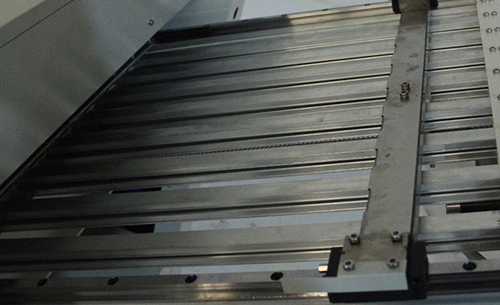

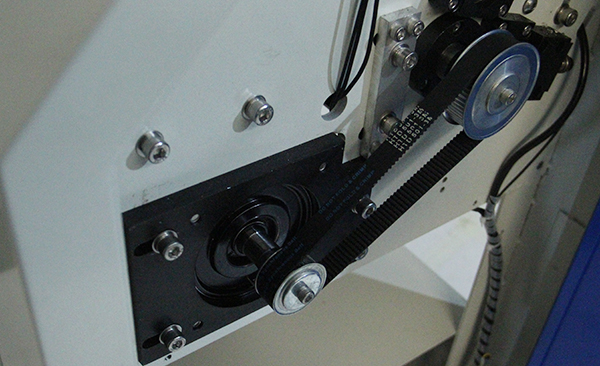

| 5. It works with servo, with rotate runing control. The machine shall be stable without problem. |

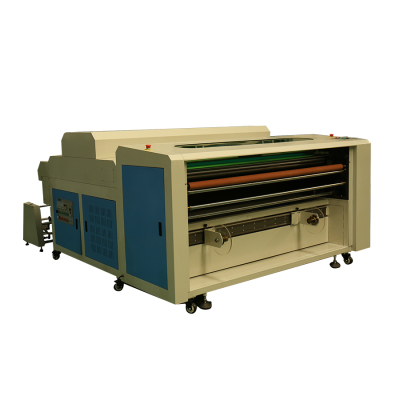

6. The high capacity calender offers strong pressure to the creasing part and easy adjustment for the level. |  |

| 7. All parts used are high quality long time tested parts with CE standard wiring system |

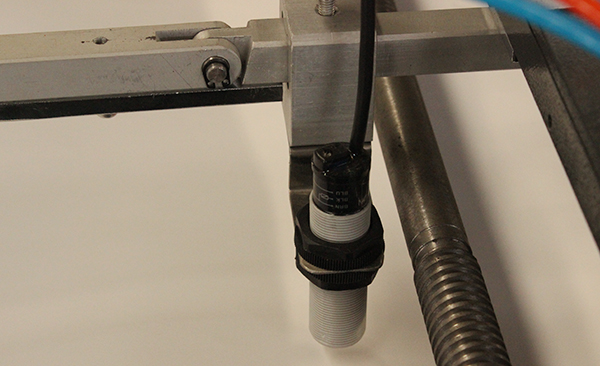

8. The sensor can sense the paper distance and make the creasing and folding in a correct position |  |

| 9. The machine can make 10 multiple crease. So we can use it for cover function also. |

Multiple Applications:

Whether you are in printing business or photography bussiness, ACF is very helpful to finish the work without cracking or curling.

Customer Feedback:

Double 100 specialize in advanced coating solutions meticulously engineered to enhance the quality and durability of your printed materials. Explore our comprehensive range of coating machines tailored to suit every aspect of your print finishing needs across various industries:

High efficiency automatic creasing and folding machines play a pivotal role in modern printing and packaging industries. Designed to streamline the production of folded materials such as cartons, brochures, and labels, these machines enhance productivity while ensuring precision and quality. This article provides a detailed technical analysis of such machines, covering their working principles, engineering features, regulatory standards, and operational best practices.

What is a High Efficiency Automatic Creasing and Folding Machine?

An automatic creasing and folding machine is an industrial device engineered to create precise creases and folds on various substrates, primarily paperboard, cardboard, and other foldable materials. The “high efficiency” designation highlights capabilities such as rapid throughput, minimal setup time, and automation features that reduce manual intervention.

Key Technical Features and Engineering Principles

Creasing Mechanism

Utilizes specially designed creasing rules and matrices to form fold lines without cracking or damaging the substrate.

Adjustable pressure controls to accommodate materials of varying thicknesses and densities.

Folding System

Employs automated folding arms, belts, or rollers to fold the substrate along the creased lines.

Multi-directional folding capabilities for complex folding patterns (e.g., Z-fold, C-fold, gate fold).

Automation and Control

Integrated PLC (Programmable Logic Controller) systems manage machine operations, allowing precise control over speed, fold angles, and sequence.

Touchscreen HMI interfaces enable real-time monitoring, diagnostics, and parameter adjustments.

Material Handling

Vacuum or mechanical feeding systems ensure consistent substrate input.

Output conveyors or stacking systems for efficient collection of finished products.

Throughput and Efficiency

Capable of processing 5,000 to 30,000 sheets per hour depending on machine model and substrate.

Quick job changeovers supported by memory presets reduce downtime.

Materials Compatibility

Paperboard thickness ranging from 200 gsm to 1000 gsm.

Cardboard sheets for packaging and displays.

Specialty materials such as synthetic paper, laminated sheets, and lightweight plastics.

Industry Standards and Regulatory Compliance

ISO 9001: Quality management systems for manufacturing and product consistency.

CE Marking: Compliance with European safety, health, and environmental requirements.

ANSI B11.20: Safety requirements for mechanical power presses, applicable for creasing tools.

RoHS Directive: Restriction of hazardous substances in electrical and electronic equipment.

OSHA Guidelines: Ensuring workplace safety during operation and maintenance.

Installation and Operational Best Practices

Site Preparation:

Ensure stable flooring to minimize vibrations.

Provide adequate space for operator movement and maintenance access.

Operator Training:

Emphasize safety procedures including lockout/tagout during maintenance.

Train on parameter adjustments and troubleshooting.

Maintenance:

Routine lubrication of moving parts and inspection of creasing rules for wear.

Regular calibration of folding angles and pressure settings.

Quality Control:

Periodic inspection of crease sharpness and fold alignment.

Sample testing for substrate integrity post-processing.

Frequently Asked Questions (FAQs)

Q1: What factors determine the creasing quality?

A: Material type, thickness, creasing rule profile, and pressure settings significantly influence crease sharpness and substrate integrity.

Q2: Can this machine handle custom fold patterns?

A: Yes, programmable control systems allow for complex fold sequences and custom jobs.

Q3: How is downtime minimized during job changes?

A: Memory presets and modular tooling facilitate rapid setup and reduce transition times.

Q4: What safety features are included?

A: Safety guards, emergency stop buttons, and interlock systems comply with industry safety standards.

Conclusion and Call to Action

High efficiency automatic creasing and folding machines are essential assets in high-volume printing and packaging workflows. Their precision, speed, and automation capabilities significantly improve operational productivity while maintaining product quality and safety.

We offer expert consultation, installation support, and after-sales service tailored to your production requirements. For detailed specifications, demonstrations, or technical assistance, contact us today.

Related News

Submitted successfully

We will contact you as soon as possible