photo album binding machine

Professional Photo Album Making Machine

Include all functions: creasing, binding/hot binding, hot pressing/cold pressing, Digital cutter, roundcorner cutter, hard cover making. and silent Air compressor.

Suitable for daily book production 5 books to 200 books

Suitable for worker of average height 160cm and above.(5.25feet+)

Machine life span 15year+, warranty 3years

Heavy Duty Machine 450kg, suitable for international transportation

Work for Inner sheets self adhesive and hot melt, Pressing temp ranging from 0--80degrees.

Factory Store, ensure immeditely 24h*7 service.

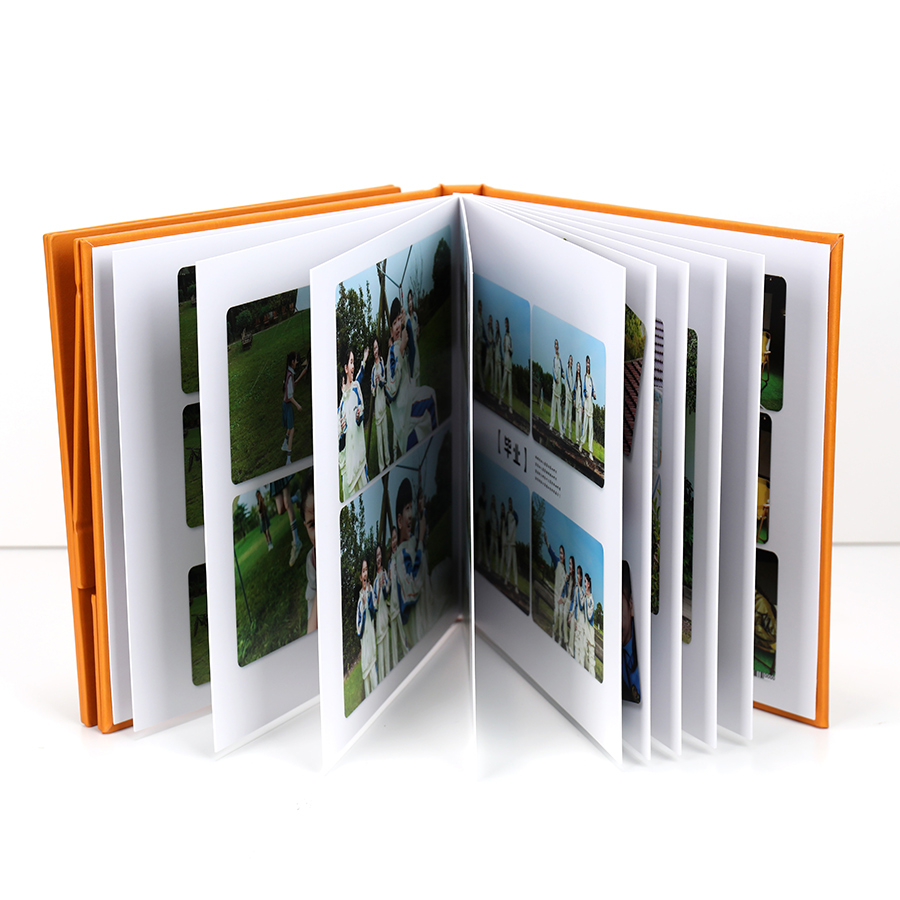

Double 100, leading the industry as the premier manufacturer of photo album binding machines, is excited to unveil the ST-6Z, a model that epitomizes our commitment to unmatched quality and superior service. This robust photo album making machine is crafted for flawless layflat binding, creating breathtaking double-page spreads and ensuring seamless assembly, resulting in professional-grade albums with every use. Its sturdy construction and advanced cutting functions make the ST-6Z perfectly suited for handling hard PVC or hot melt sheets, guaranteeing flawless photo album production.

The ST-6Z is a cutting-edge All in One photo album making machine, tailored with a suite of features specifically for hard cover album creation. It offers simple heat binding, precise crease measurement, dual-layer heating for even pressing, and accurate cutting with integrated safety features. This multifunctional photo album making machine, adaptable to various sheet types, includes a foldable hard cover and work table, a quiet air compressor, and a solid round corner cutter for a polished decorative finish.

Meeting CE standards for its electrical components, the ST-6Z is engineered for precision and longevity. It is the perfect choice for anyone looking for a reliable and multifunctional photo album binding machine from the esteemed Double 100 brand. The machine's user-friendly operation, extensive technical support, and training programs assist both professional photographers and hobbyists in producing top-notch albums. Whether you're considering the album making machine price or its multifunctional features, the ST-6Z by Double 100 is a remarkable investment in photo album maker technology. For those in search of an album binding machine for sale, the ST-6Z is a must-consider option.

Designedfor durability, precision cutting, and folding, our machines deliver flawless results. From PVC albums to hot melt cardboard, double 100 unlocks the potential of youralbums with high-quality cutter and adhesive glue sheets.

Main Characteristics:

Varified Consumables Use: Various materials(hot and cold)in customized size based on your needs.

Works with Hot Melt Sheets: Hot melt sheet cheaper while more harder than adhesive PVC, and never break and environment friendly.

Perfect Finished Album: More neat aligement, album persist longer for high pressure pressing, album edge more smooth, layflat.

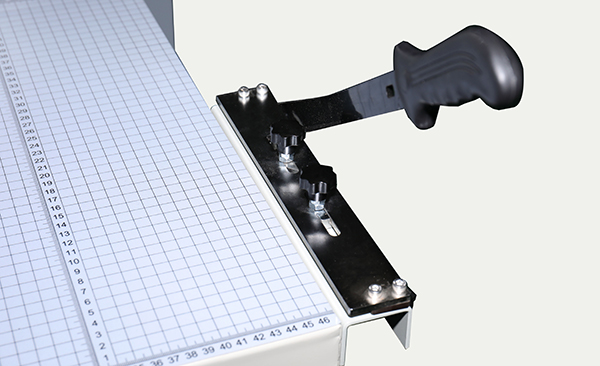

Powerful Cutter for Hard PVC: Hard PVC need heavy duty cutter to work longer, also cutting effect is the most direct visual effect showing.

Humanized Operation Design: Upright design avoids stoop labour; easy to use and operate, helping to reduce training time and increase efficiency.

Durable Frame Construction: Safe in transportation, and long lasting machine working time, worthy investment to earn back more.

With Training and Technical Support: Immediately to have machine create value, and learn the newest trend for the business. 3 year warranty and all life service.

Practical Functions: Have the most commonly used functions for bookbinding, offering a great value with low cost.

Solutions Provided: We offer a full range solutions for different photo album productions with machines and consumables.

Easy Maintenance: Low maintenance requirements.

Product Parameter:

Specifications | |

Mode | ST-6Z |

Operation principle | Electric and pneumatic |

Max size of album | 18*18inch(48*96cm) |

Cutting height | 7cm |

Paper cutting mode | 460 digital cutter |

Cutting size | 46*46*7cm |

Pressing | cold/hot |

Pressing size | 40*50*10cm |

Pressing height | 20cm |

Max. hot pressing temperature | 150 degree |

Grooving size of cover | A8cm |

Grooving blade width | 2mm |

Max size of binding | 48cm |

Max height of binding | 5cm |

Max size of cover making | 18 inch |

Comer cutter | R3-r10 too choose one |

Voltage | 220v/60hz/50hz/3.5kw |

Weight(N.W/G.W) | 450kg/480kg |

Machine size | 1.5*1.06*1. 42m |

Packaga size | 1.6*1.16*1.52 |

Other Models | J-5,ST-6S,ST-7S,DT-4S,J-5,P-2 allin one album |

Product Details and Characteristics:

Our Advantage

·Main Characteristics·

| The machine is of slide binding, making it easyfor operator, and the magnetic is very helpfulfor the book position. lmm panel ensure thealbum open totally fat |

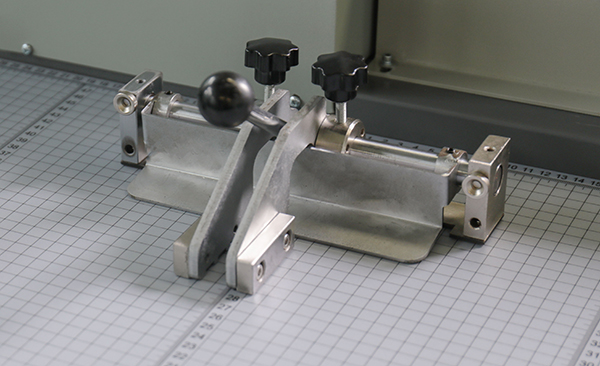

The creasing part with the whole facemeasurement and strong magnetic ruller ensuring correct creasing |  |

| Wheels for adjusting the material thickness,coating thickness and doctor blade to ensure themachine workingin a perfect condition |

High precise album cutter is speciallydesigned for cutting album which maymade by PVC or glued cardboard.With IR ray to ensure the safety of theoperato |  |

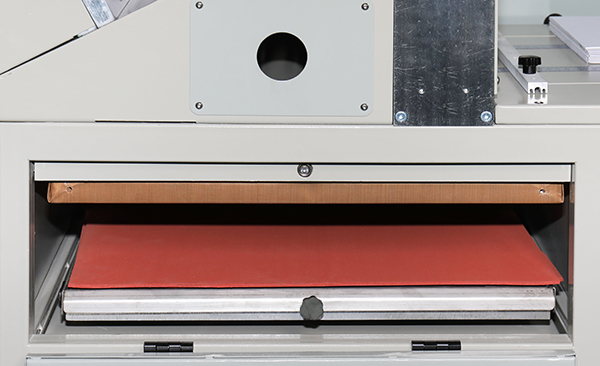

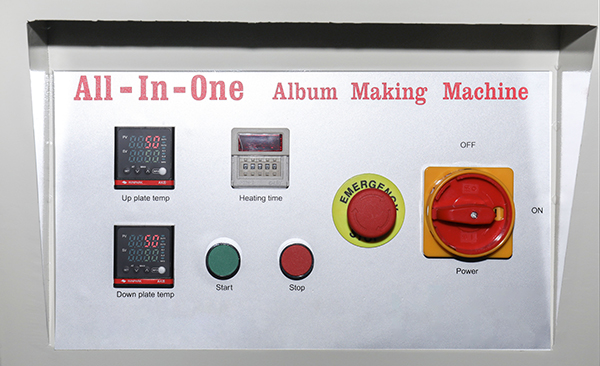

| The machine can work with both hotmelt sheets and self adhesive sheets.The pressing power is big and ensurableAnd Big control panel |

The side table can work as a working tableor is used to make hard corver. lt include allthe functlons for making hard cover: centrapositlon , photo comer trimming |  |

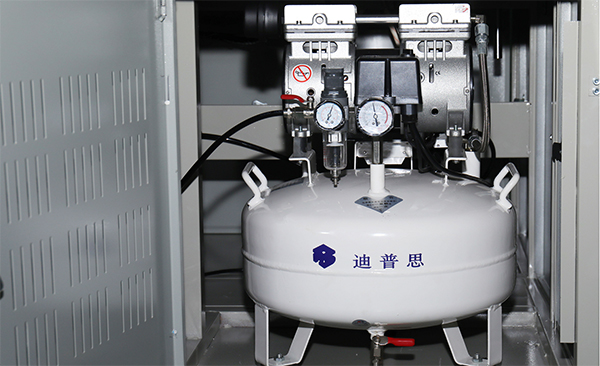

| High volumn silent air compressoris equippment inside the machine,offering sustainable air supply |

The heavy duty round corner cutter,ensuring the comer was cut smoothly |  |

Application:

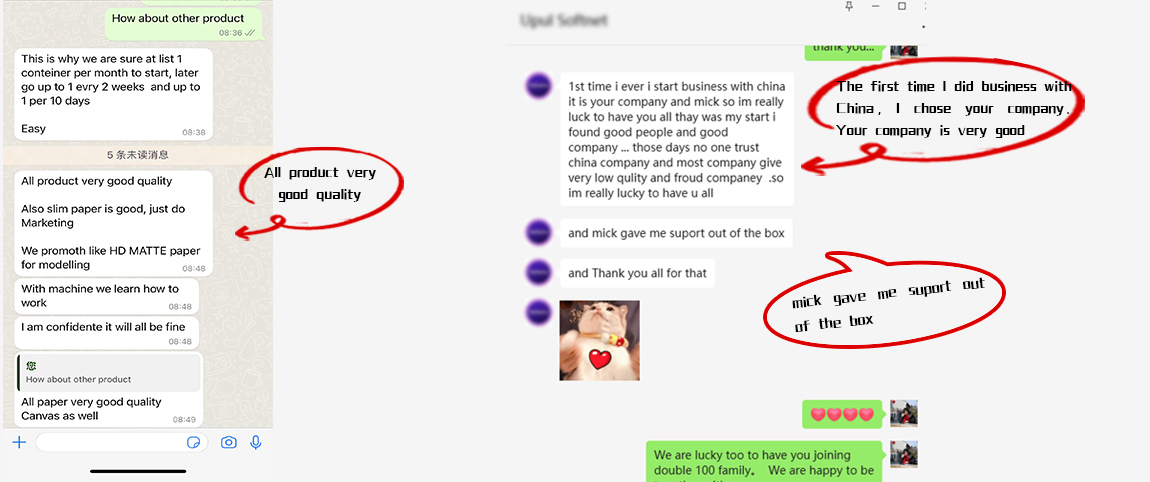

Customer Feedback:

Double 100 provides innovative coating solutions that significantly enhance the quality and durability of your printed materials. Explore our full range of coating machines, customized to meet print finishing needs across a wide range of industries.

Post-Print Enhancement: UV and aqueous coating machines for paper prints, labels, stickers, corrugated cardboard, large-format materials, and boards help improve vibrancy and offer durable protection against water, sunlight, and abrasion.

Pre-Print Preparation: With our primer coating technology, you can enhance the surface of paper prints and ceramics, improving image clarity while providing scratch and water resistance. We are seeking distributors from all corners of the globe to bring our innovative solutions to new markets.

In the era of digital photography, the demand for premium, physically bound photo albums remains high—especially in the wedding, graduation, and personalized gift markets. A photo album binding machine is a crucial piece of equipment for professionals looking to produce high-quality albums with durability and aesthetic value. This article provides a detailed, technically grounded guide on selecting, using, and maintaining photo album binding machines, covering engineering considerations, safety protocols, industry standards, and best practices.

Table of Contents

What is a Photo Album Binding Machine?

Types of Photo Album Binding Machines

Engineering Principles Behind Binding Machines

Key Materials and Components

Regulatory Compliance and Safety Standards

Factors to Consider When Choosing a Binding Machine

Operation Guidelines and Common Issues

Maintenance Best Practices

FAQs

Conclusion & Professional Call to Action

1. What is a Photo Album Binding Machine?

A photo album binding machine is a specialized device used to assemble and bind printed photographs or photo sheets into a cohesive book-like structure. These machines are engineered to ensure precision, alignment, adhesive strength, and finish quality, particularly for thick or laminated photo pages.

2. Types of Photo Album Binding Machines

There are several types available on the market:

Thermal Binding Machines: Use heat-activated glue; suitable for fast operations.

Perfect Binding Machines: Often used for commercial albums, with PUR (polyurethane reactive) adhesives.

Lay-Flat Binding Machines: Enable albums to open completely flat; common in premium photo books.

Hardcover Casing-in Machines: Attach hard covers to previously bound inner blocks.

3. Engineering Principles Behind Binding Machines

Photo album binding machines operate on a few core engineering principles:

Thermodynamics: Adhesive bonding systems require precise temperature control to activate glue without damaging paper substrates.

Mechanical Alignment: Critical for edge uniformity, especially in lay-flat formats.

Pressure Application: Uniform pressure ensures long-term durability and adherence.

Cycle Timing: Affects throughput, especially in semi-automated and automated systems.

Engineers often design machines using a combination of steel frames, aluminum work surfaces (for thermal efficiency), pneumatic or servo-driven pressing plates, and programmable logic controllers (PLCs) for consistent performance.

4. Key Materials and Components

Adhesives: EVA, PUR, or hot-melt types, each with varying cure times and strength profiles.

Cover Boards: Often made of greyboard, chipboard, or MDF, with PU or paper laminates.

Binding Sheets: Laminated photo paper, typically 200–400 gsm.

Spine Liners & Hinges: Add flexibility and allow albums to open without spine cracking.

5. Regulatory Compliance and Safety Standards

When using or sourcing a photo album binding machine, ensure compliance with the following standards:

CE Marking (EU): Indicates electrical and mechanical safety compliance.

UL Certification (US): For electronic components.

ISO 9001: Quality management system certification.

RoHS Compliance: Restricts use of hazardous substances in electrical equipment.

Operators should follow OSHA machine safety guidelines and use PPE when operating thermal or hydraulic components.

6. Factors to Consider When Choosing a Binding Machine

A. Volume & Throughput

Low-Volume: Manual or semi-auto machines (10–50 albums/day).

Medium-Volume: Semi-automated machines (up to 150 albums/day).

High-Volume: Fully automated lines (500+ albums/day).

B. Binding Type Required

Do you need lay-flat, perfect-bound, or hardcover casing?

C. Material Compatibility

Check for compatibility with laminated, gloss, or synthetic sheets.

D. Budget Constraints

High-end systems offer automation but require significant investment.

E. Footprint and Electrical Requirements

Some machines require 3-phase power and ventilation for thermal operations.

7. Operation Guidelines and Common Issues

General Workflow:

Align inner pages using a jig or guide rail.

Apply adhesive using heated rollers or gluing heads.

Compress under uniform pressure.

Attach spine liner and cover.

Cool and cure for the recommended duration.

Common Problems:

Misalignment: Use calibration tools to align inner sheets.

Weak Binding: May indicate low adhesive temperature or humidity interference.

Air Bubbles in Cover: Caused by poor pressing or surface contaminants.

8. Maintenance Best Practices

Daily: Clean glue tanks and pressure plates.

Weekly: Lubricate mechanical parts and check PLC settings.

Monthly: Inspect heating elements and pressure regulators.

Annually: Conduct full calibration and software updates.

Always disconnect from power before maintenance and consult the technical manual.

9. Frequently Asked Questions (FAQ)

Q1: Can I use the same machine for hardcover and softcover albums?

A: Some advanced models allow for modular configurations, but most entry-level units are specialized.

Q2: What glue is best for photo album binding?

A: PUR adhesive offers superior flexibility and durability, especially for thick pages.

Q3: How long does a photo album need to cure after binding?

A: Generally, 12–24 hours depending on adhesive type and ambient conditions.

Q4: Is lay-flat binding more difficult?

A: Yes. It requires more precise alignment and often additional materials like hinge sheets or floating hinges.

10. Professional Call to Action

Selecting and operating a photo album binding machine requires careful attention to technical specifications, production goals, and compliance standards. Whether you are launching a small personalized photo book line or scaling up to industrial volumes, understanding the engineering and material science behind binding technology is essential.

We specialize in providing expert guidance and high-performance binding solutions tailored to your operational scale. For customized consultations, training materials, or machine recommendations based on your specific production needs, contact our technical team today.

Company Strength:

Innovative Printing Solutions

At Jinan Cmall International Trading Co., Ltd, we are your trusted partner for state-of-the-art printing solutions. We proudly represent Double 100, an industry leader in layflat photo book machines, glued PVC sheets, and UV coating machines. With over two decades of experience, our commitment to superior quality and continuous innovation sets us apart.

Comprehensive Product Range

Double 100 offers an extensive array of printing and packaging solutions, from manual equipment to fully automated systems. Our product portfolio spans from layflat photo book machines and hardcover makers to a variety of coating machines. All our products are crafted to meet high standards and come with a 3-year warranty for added security.

Global Reach & Reliability

Cmall International has built strong partnerships in over 90 countries, working with major industry players like HP Indigo, Canon, and Konica Minolta. Our competitive prices, customized solutions, and outstanding reliability make us the preferred partner for print shops globally. Join us to experience efficient, high-quality service for all your printing needs.

Client Positive Feedback:

Related News

Submitted successfully

We will contact you as soon as possible