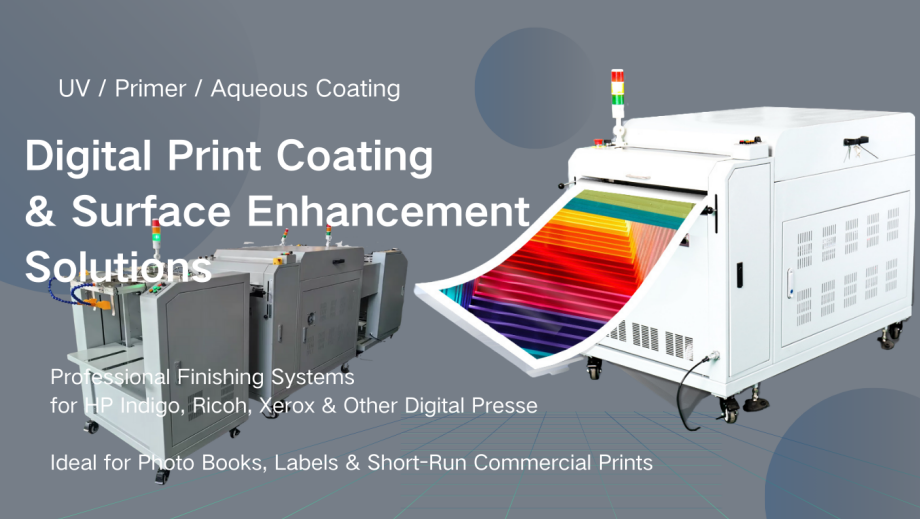

Digital Printing Coating Solutions

Professional UV & Water-Based Finishing Systems for Digital Print Shops & HP Indigo Users

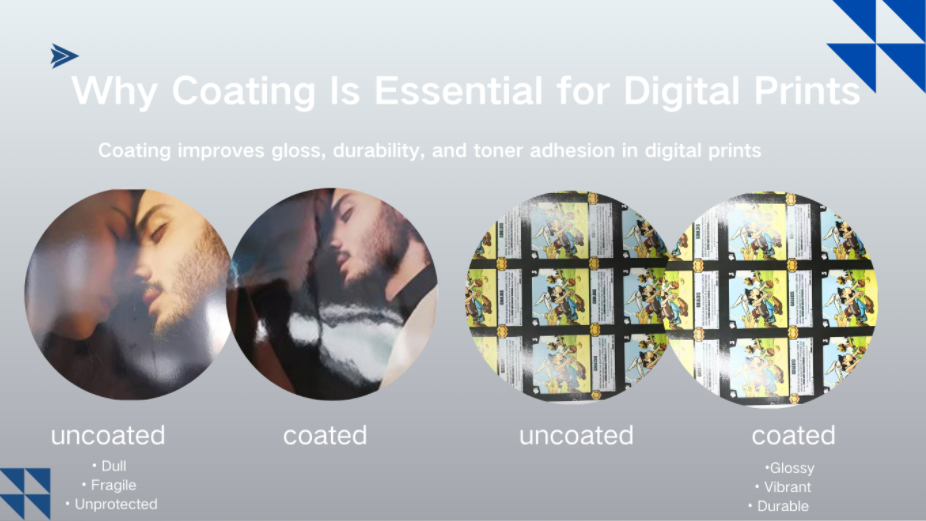

1. Why Digital Printing Needs Professional Coating?

Modern digital printing—whether toner-based (Xerox, Ricoh, Konica Minolta, Canon) or liquid electro-ink (HP Indigo)—faces three universal challenges:

① Easy Scratching & Poor Durability

Toner and electronic inks sit on the paper surface → friction causes scuffing.

② Weak Adhesion on Coated Stocks

On glossy, cast-coated, art papers, ink adhesion is weak → coating or primer is required.

③ High Production Cost of Lamination Films

Film lamination is fast but expensive for small jobs, and creates plastic waste.

That's why thousands of global print shops are shifting to UV coating + Primer coating + Water-based coating as a flexible, lower-cost finishing method.

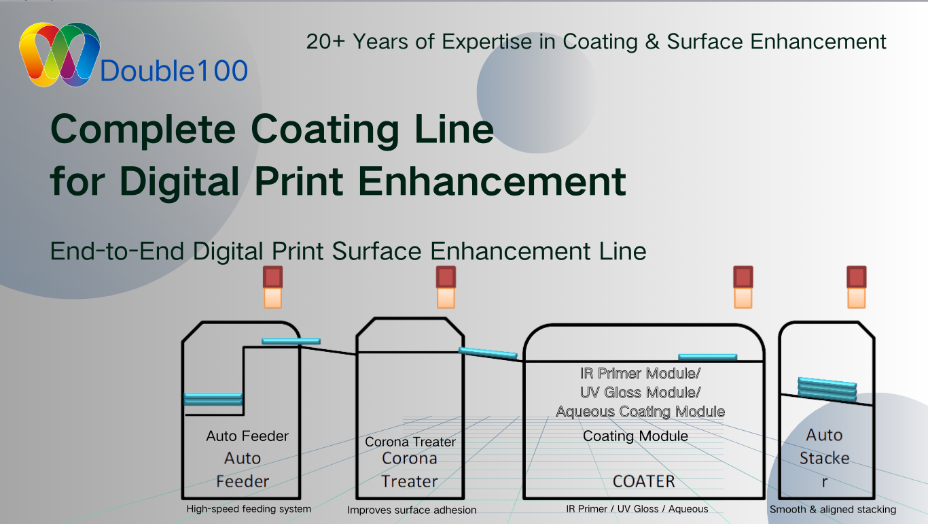

2. Double100 Digital Printing Coating Line

Your complete offline finishing line for toner, e-ink, and HP Indigo machines

⭐ Your Coating Line Can be Configured as:

Feeder (Optional)

For high-volume digital printers.Corona Treatment

Solves adhesion issues → mandatory for digital toner & Indigo.Primer Coating (HP Indigo Special Primer / Toner Primer)

Improves surface anchoring → prevents peeling & cracking.Water-Based Coating (Glossy / Matte / Soft-Touch)

Low cost, eco-friendly, suited for book covers & marketing materials.UV Coating (Glossy / Matte / Textured)

High hardness (up to 5H), scuff-resistant, ideal for commercial prints.IR/Hot Air Drying System

Fast-drying for water-based coats & primer.Stacker / Delivery Section

Neat offline collection.

👉 All modules can be integrated into one PRO line or used separately.

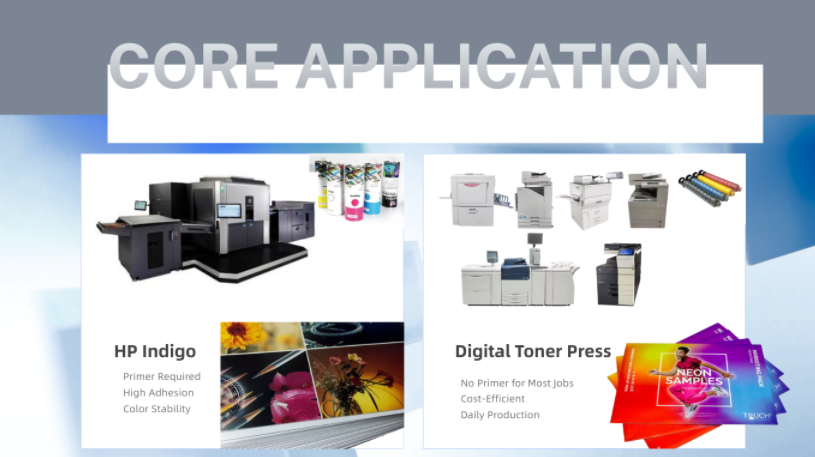

⭐ Two Core Market Segments We Serve

A. HP Indigo & High-End Digital Press Users

(Indigo12000 / 7900 / 5900 / liquid electrophotographic printing)

These customers require:

Primer coating before printing (Indigo mandatory)

Topcoat protection after printing

High-speed, scratch-resistant finishing

Color stability (ΔE < 1.5)

Compatibility with coated & synthetic papers

Double100 Offers:

Indigo Primer Coating System (PRO Series)

Corona Pre-Treatment Unit

UV Topcoat Module (Gloss / Matte / Anti-scratch)

Water-Based Topcoat (Soft Touch / Matte)

Indigo Cleaning Machine

Typical Line Configuration for Indigo:

Feeder → Corona → Primer → Drying → UV/Water-Based → Stacker

Key Benefits for Indigo Production

✓ Eliminates ink peeling

✓ Gloss/matte effect options

✓ High adhesion rating up to 4–5B

✓ 5-year outdoor durability (UV varnish)

✓ Works for commercial prints, packaging, luxury brochures

B. Global Digital Print Shops (Xerox, Ricoh, KM, Canon, Chinese Toner Machines)

This group represents the world's largest digital printing volume.

The Pain Points:

Toner scratches easily → complaints from customers

Lamination film too expensive for short runs

Need fast finishing that supports daily jobs

Small shop space

Double100 Recommended Systems:

480 UV Coater (Entry Level)

650 UV Coater (Mid-range)

PRO 650 Offline Finishing Line

Water-Based Automatic Coater (Feeding–Coating–Stacking)

Applications:

Photobooks

Corporate brochures

Training manuals

Invitations

Menus

Flyers

Book covers

Benefits for Print Shops

✓ Reduce lamination cost by 60%

✓ No lamination film stock needed

✓ Instant curing for quick delivery

✓ Highly profitable for small-job finishing

✓ Compatible with all digital output

⭐ Coating Liquids We Supply

To deliver complete coating solutions, Double100 provides liquid options:

Primer for HP Indigo & Toner Printing

Perfect anchoring layer → prevents ink peeling.Water-Based Gloss / Matte / Soft Touch Coatings

Eco-friendly & cost-effective.UV Coating Oils (Gloss / Matte / Anti-scratch / Texture)

Suitable for high-end brochures & commercial prints.Special Oils for Playing Cards / Art Paper

Example: Your recent playing-card coating case—same machine, different oil → problem solved.

👉 By offering both machines + liquids, your solution is complete and highly competitive.

⭐ Machines Recommended for Digital Printing Coating

Sheet-Fed Systems

PRO 650 Multi-Function UV/Primer/Water-Based Coater

Water-Based Automatic Coater (Feed → Coat → Stack)

Roll-to-Roll (For small label & digital packaging)

R2R-350 Label UV Coater with Auto Web Guiding (EPC)

1350 / 1600 Wide Roll Coater for posters, signage, vinyl, boards

⭐ UV Coating vs Film Lamination

For daily digital print jobs → UV is the most profitable finishing method.

⭐ Industry Applications

Digital photobooks

Corporate brochures

On-demand books

Menus & invitations

Business cards

Luxury print marketing

Label coating (small runs)

⭐ Why Choose Double100?

Independent R&D of sheet-fed & roll-fed coating systems

One of the few global suppliers offering machines + liquids + full line integration

Expertise from operating our own photobook factory & Indigo12000 machines

Customizable solutions for small print shops to mid-size factories

Global installation, training, and after-sales support

⭐ Call to Action

Need a coating solution for your digital printing business?

Tell us your printer model, materials, and daily volume — our engineers will design the best-fit line for you.

📩 Contact Double100 for a tailored coating solution.